Time and date

CONSTRUCTION DIRECTORY

Challenge Europe Ltd Contact Details

Telephone

Click to view

Fax

01234 327349

Website

Contact

Kevin Moorcroft

Email

Address

Shuttleworth Road

Goldington

Goldington

Bedford

Bedfordshire

MK41 0EP

England UK

Opening Hours

Monday

09:00-17:30

Tuesday

09:00-17:30

Wednesday

09:00-17:30

Thursday

09:00-17:30

Friday

09:00-17:30

Saturday

Closed

Sunday

Closed

Other Dates

About Challenge Europe Ltd

Challenge (Europe) Ltd is an ISO9001 stockist and distributor of threaded fasteners, with an emphasis on supplying manufacturing companies located within the UK with specialist standard or custom components.

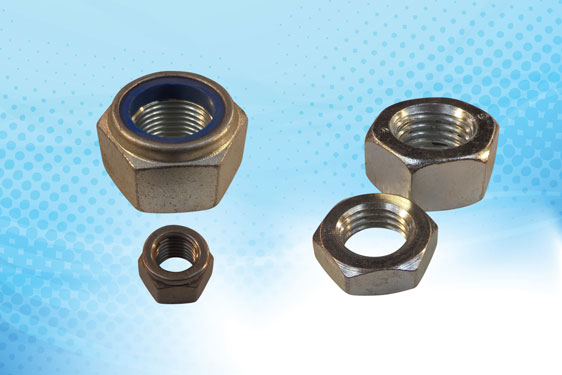

This includes extensive stock and application specific supply capability for screws and bolts of all types including machine screws, self-drilling screws, hammer drive screws, wood screws, self-tapping, thread-forming screws and sems. Bolts include Hex head, construction floor anchors, coach bolts and studding. They have an extensive stock of socket head screws as well as nuts, cage nuts, rivet nuts, Tee nuts, weld nuts, u nuts, wing nuts, barb nuts and combi nuts. Washers are stocked in depth from flat and shake proof to mudguard, copper grip and terminal cup types, to crinkle washers, sealing and Belville washers, spring and cup washers, as well as O rings. Rivets include blind and tubular, alongside split cotter pins, dowel/groove pins, weld studs, tension pins, self-clinching and brass threaded inserts.

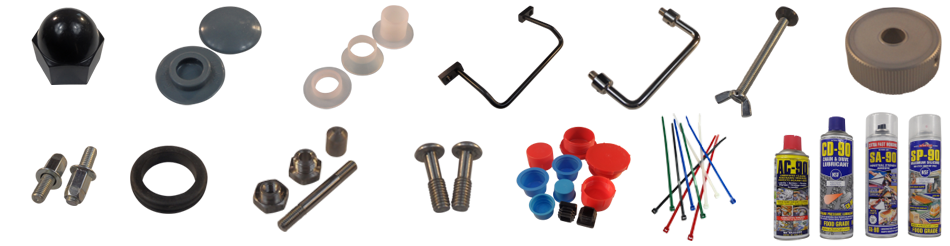

Challenge also carry useful ancillary products, such as grommets, plugs and screw caps, carrying handles, valve knobs, cable ties and the range of Action Can lubricants, sprays and aerosols.

Challenge operates Project Manufacturing Partnerships for subcontract manufacture, sub-assembly and logistic supply. These have developed over many years from simple kitting processes to cover supply chain management, including co-operative product development, tooling control and global sourcing through to stock monitoring.

Project Manufacturing Partnerships have developed in a number of ways from the original threaded fastener distribution function, while threaded product ranges have expanded to include more sizes, more materials, and more finishes. New products have been included, such as rivets/pins and sole UK distributorship of the Dubo ring, together with associated products such as the toothed collar ring, Korrex nut caps, and insulating bushes. Challenge are now suppliers to customers in many market sectors – this includes associations with the electronics industry, building products, construction industry, automotive industry and white goods manufacturers.

Quality has always been a top priority for Challenge, reflected both in the product range they stock, and in the service they provide. Challenge gained the ISO9001 award for quality in 1996, and the company is a member of the Engineering Industries Association. The Challenge service enables them to supply systems such as Vendor Managed Inventory, Kanban, JIT, and Linefeed. The company also offers a specialised sub-assembly and packing service, allowing customers products to be supplied in the most efficient format. Combined with the availability of their own UK delivery fleet, the service that Challenge offers cannot be surpassed.

This includes extensive stock and application specific supply capability for screws and bolts of all types including machine screws, self-drilling screws, hammer drive screws, wood screws, self-tapping, thread-forming screws and sems. Bolts include Hex head, construction floor anchors, coach bolts and studding. They have an extensive stock of socket head screws as well as nuts, cage nuts, rivet nuts, Tee nuts, weld nuts, u nuts, wing nuts, barb nuts and combi nuts. Washers are stocked in depth from flat and shake proof to mudguard, copper grip and terminal cup types, to crinkle washers, sealing and Belville washers, spring and cup washers, as well as O rings. Rivets include blind and tubular, alongside split cotter pins, dowel/groove pins, weld studs, tension pins, self-clinching and brass threaded inserts.

Challenge also carry useful ancillary products, such as grommets, plugs and screw caps, carrying handles, valve knobs, cable ties and the range of Action Can lubricants, sprays and aerosols.

Challenge operates Project Manufacturing Partnerships for subcontract manufacture, sub-assembly and logistic supply. These have developed over many years from simple kitting processes to cover supply chain management, including co-operative product development, tooling control and global sourcing through to stock monitoring.

Project Manufacturing Partnerships have developed in a number of ways from the original threaded fastener distribution function, while threaded product ranges have expanded to include more sizes, more materials, and more finishes. New products have been included, such as rivets/pins and sole UK distributorship of the Dubo ring, together with associated products such as the toothed collar ring, Korrex nut caps, and insulating bushes. Challenge are now suppliers to customers in many market sectors – this includes associations with the electronics industry, building products, construction industry, automotive industry and white goods manufacturers.

Quality has always been a top priority for Challenge, reflected both in the product range they stock, and in the service they provide. Challenge gained the ISO9001 award for quality in 1996, and the company is a member of the Engineering Industries Association. The Challenge service enables them to supply systems such as Vendor Managed Inventory, Kanban, JIT, and Linefeed. The company also offers a specialised sub-assembly and packing service, allowing customers products to be supplied in the most efficient format. Combined with the availability of their own UK delivery fleet, the service that Challenge offers cannot be surpassed.

Gallery

|

Click to close

|

News

08/07/2020

Challenge Europe – wire thread inserts for high-strength threads in soft materials

Specialist threaded fasteners often need help in forming the best attachment to soft core materials such as aluminium or magnesium alloys. Challenge Europe are pleased to announce their stock, advice and production service operation for a comprehensive range of wire thread inserts, available in both tanged and tangless variants, or screw thread inserts which provide high performance internal threads in castings where light weight of the complete assembly is a major issue.

These inserts provide significantly improved performance over the substrate, enabling bolt tension to be maintained under severe conditions of vibration, thermal stress and corrosive action.

Challenge Europe wire thread inserts represent an extensively proven well accepted technology and are exceptionally effective in aerospace, auto industry, electronics, medical and related industries.

Use of wire thread inserts enables manufacturer assemblers to access the best performance characteristics of a multi-material approach where combinations of metallurgy are required. Standard material is chrome nickel austenitic stainless steel which is compatible with most substrates and is both hard-wearing and corrosion-resistant.

A wide range of other materials and surface finishes are available to ensure optimum performance in a variety of thread forms and identification colours.

Further information on Challenge Europe products can be found on their website – www.challenge-europe.co.uk.

These inserts provide significantly improved performance over the substrate, enabling bolt tension to be maintained under severe conditions of vibration, thermal stress and corrosive action.

Challenge Europe wire thread inserts represent an extensively proven well accepted technology and are exceptionally effective in aerospace, auto industry, electronics, medical and related industries.

Use of wire thread inserts enables manufacturer assemblers to access the best performance characteristics of a multi-material approach where combinations of metallurgy are required. Standard material is chrome nickel austenitic stainless steel which is compatible with most substrates and is both hard-wearing and corrosion-resistant.

A wide range of other materials and surface finishes are available to ensure optimum performance in a variety of thread forms and identification colours.

Further information on Challenge Europe products can be found on their website – www.challenge-europe.co.uk.

06/07/2020

Challenge Europe address the dangers of “internet specification” of threaded fasteners

With all the benefits of the internet it has become apparent that there are dangers – who of us has not come across the life-critical disease “we have self-diagnosed” online, or the false news/conspiracy theory which can reinforce our worst fears?

At a professional industrial level, Challenge Europe often find design engineers overlook the sophistication of threaded fasteners and fall into the trap of “internet specification” or “specification by CAD system”. A practice which seems to derive from pressure of time coupled with the perception that fasteners are low-end product and that sourcing can be done over the internet, relying on urgent sample supply in case of doubt.

An experienced fastener supplier can provide a wider knowledge at the level of advice in new product development, re-engineering and in problem-solving where difficulties arise. It is increasingly difficult to find this level of expertise outside of small specialists such as Challenge Europe.

Further information on Challenge Europe products can be found on their website – www.challenge-europe.co.uk.

At a professional industrial level, Challenge Europe often find design engineers overlook the sophistication of threaded fasteners and fall into the trap of “internet specification” or “specification by CAD system”. A practice which seems to derive from pressure of time coupled with the perception that fasteners are low-end product and that sourcing can be done over the internet, relying on urgent sample supply in case of doubt.

An experienced fastener supplier can provide a wider knowledge at the level of advice in new product development, re-engineering and in problem-solving where difficulties arise. It is increasingly difficult to find this level of expertise outside of small specialists such as Challenge Europe.

Further information on Challenge Europe products can be found on their website – www.challenge-europe.co.uk.

23/06/2020

How Challenge Europe address problems of over specification in threaded fasteners

Ultimately, one can never know completely how a fastener will function in-situ until you try it which is why accelerated ageing trials and extended excess load tests are frequently performed to ascertain a realistic safety margin. Guidelines from hard-won experience can normally be accessed, but sometimes an unusual situation needs to be evaluated or perhaps a replacement of the exact same type is simply not available and a suitable replacement is required. It is easy and tempting to over-specify, but Challenge Europe can help.

Fasteners can almost be regarded as active components, given the changing loads and environments they are often called upon to compensate for in their daily service. The simple act of holding together two separate components requires a balancing of forces – this is a complex matter often addressed by application of a “safety margin” judged to be sufficient to deal with the unknowns involved.

However, some industries deal with much more life and performance critical situations than others and so the concept of designing for a product lifetime has evolved – in one way to ensure that the specification is adequate, but on the other to time-limit the expectation, and so ensure that proper maintenance is mandated.

Aerospace, automotive and rail industries all follow this design for a specific lifetime philosophy – an approach rarely used elsewhere - and sometimes this leads to over specification in products which do not need it. This over specification is often a comfort issue, as a sort of safety margin which often makes the custom spec prohibitively expensive if not actually impractical. Over specification is a significant potential problem in the fastener industry.

This generally occurs in applications where there are issues of weight and space but where cost is secondary because of the safety critical nature of the situation. However sometimes given a minimum lifetime expectancy there can be a tendency to “play it safe” and add a safety margin on top of a safety margin, leading to gross over specification, e.g. going up one or two sizes with consequent weight and space implications. Calling for an exotic and expensive alloy where a lower-cost high-grade treated steel would be more appropriate. Over specifying one fastener may not be a problem but over specifying thousands can make a big difference overall.

Design for a specific lifetime is often a highly skilled art of combining knowledge from different areas, e.g. specific performance of the fastener, effect of varying material, options for head types and the stress they involve, stresses inbuilt into the fastener from its manufacturing process or treatment - a solution which can be achieved in concert with a fastener specialist such as Challenge Europe.

Further information on Challenge Europe products can be found on their website – www.challenge-europe.co.uk.

Fasteners can almost be regarded as active components, given the changing loads and environments they are often called upon to compensate for in their daily service. The simple act of holding together two separate components requires a balancing of forces – this is a complex matter often addressed by application of a “safety margin” judged to be sufficient to deal with the unknowns involved.

However, some industries deal with much more life and performance critical situations than others and so the concept of designing for a product lifetime has evolved – in one way to ensure that the specification is adequate, but on the other to time-limit the expectation, and so ensure that proper maintenance is mandated.

Aerospace, automotive and rail industries all follow this design for a specific lifetime philosophy – an approach rarely used elsewhere - and sometimes this leads to over specification in products which do not need it. This over specification is often a comfort issue, as a sort of safety margin which often makes the custom spec prohibitively expensive if not actually impractical. Over specification is a significant potential problem in the fastener industry.

This generally occurs in applications where there are issues of weight and space but where cost is secondary because of the safety critical nature of the situation. However sometimes given a minimum lifetime expectancy there can be a tendency to “play it safe” and add a safety margin on top of a safety margin, leading to gross over specification, e.g. going up one or two sizes with consequent weight and space implications. Calling for an exotic and expensive alloy where a lower-cost high-grade treated steel would be more appropriate. Over specifying one fastener may not be a problem but over specifying thousands can make a big difference overall.

Design for a specific lifetime is often a highly skilled art of combining knowledge from different areas, e.g. specific performance of the fastener, effect of varying material, options for head types and the stress they involve, stresses inbuilt into the fastener from its manufacturing process or treatment - a solution which can be achieved in concert with a fastener specialist such as Challenge Europe.

Further information on Challenge Europe products can be found on their website – www.challenge-europe.co.uk.

03/06/2020

Machine Screws - Challenge Europe discuss what you would use these products for

Machine screws are used almost everywhere! They are ubiquitous in assembly roles world-wide, especially for fixing accessories to castings, fixing castings together, often with nuts – fixing covers in place – from marine situations to aerospace, packaging to electronics.

The materials choice begins with low-grade steel for general purpose on up to high-force situations requiring high-grade steel, elsewhere calling for brass or copper for electrical conductivity, then covering corrosive environments where a stainless steel is needed – even to very high temperature or extremely aggressive environments which may need exotic alloys such as Hastelloy, Elgiloy, Titanium etc.

Typical issues include vibration loosening but this is now reliably addressed by a range of friction-based or washer-type solutions. However, significant care is needed where electro-galvanic action may be envisaged, i.e. where a mix of different materials is envisaged with conflicting electro potential.

The basic format of threaded shank and load-spreading head is capable of extensive adaptation with choices of thread form – although typically these will be an ISO Metric specification. Screw heads however are subject to a very wide range of shapes and design concepts to reduce vibration loosening, facilitate automatic installation, resist vandalism/unauthorised removal, or to create a smoother, more easily cleaned surface, e.g. in the food industry, or to facilitate especially high torque settings, such as may be required in high-performance industries such as aerospace or automotive applications.

Further information on machine screws from Challenge Europe can be found at www.challenge-europe.co.uk/threaded-products-screws/machine-screws.

The materials choice begins with low-grade steel for general purpose on up to high-force situations requiring high-grade steel, elsewhere calling for brass or copper for electrical conductivity, then covering corrosive environments where a stainless steel is needed – even to very high temperature or extremely aggressive environments which may need exotic alloys such as Hastelloy, Elgiloy, Titanium etc.

Typical issues include vibration loosening but this is now reliably addressed by a range of friction-based or washer-type solutions. However, significant care is needed where electro-galvanic action may be envisaged, i.e. where a mix of different materials is envisaged with conflicting electro potential.

The basic format of threaded shank and load-spreading head is capable of extensive adaptation with choices of thread form – although typically these will be an ISO Metric specification. Screw heads however are subject to a very wide range of shapes and design concepts to reduce vibration loosening, facilitate automatic installation, resist vandalism/unauthorised removal, or to create a smoother, more easily cleaned surface, e.g. in the food industry, or to facilitate especially high torque settings, such as may be required in high-performance industries such as aerospace or automotive applications.

Further information on machine screws from Challenge Europe can be found at www.challenge-europe.co.uk/threaded-products-screws/machine-screws.

11/05/2020

Challenge Europe – ex-stock threaded fasteners for challenging times

Challenge Europe have always had a belief that “you can’t sell from an empty basket” and so have had a long-term policy of stocking heavily to ensure they are able to support changes in customer demand.

Therefore, Challenge are pleased to announce that they have good stocks of threaded fasteners so that customers can be assured of robust supply. Of course, this is especially important at this time of general lock-down when it may prove difficult to access many existing channels – and will be just as important when the locks come off and urgent demand is felt in the recovery phase.

It is already clear that the medical device and associated equipment industries are stretched producing many times their usual output of beds, ventilators etc. to note only the headline items. Supply of hardware items such as threaded fasteners – screws, bolts, nuts, washers etc. is being supported by specialist expert stocking distributors like Challenge Europe.

Challenge Europe invite any company experiencing supply difficulties on these items, to contact them for an urgent service.

Further information on Challenge Europe products can be found on their website – www.challenge-europe.co.uk.

Therefore, Challenge are pleased to announce that they have good stocks of threaded fasteners so that customers can be assured of robust supply. Of course, this is especially important at this time of general lock-down when it may prove difficult to access many existing channels – and will be just as important when the locks come off and urgent demand is felt in the recovery phase.

It is already clear that the medical device and associated equipment industries are stretched producing many times their usual output of beds, ventilators etc. to note only the headline items. Supply of hardware items such as threaded fasteners – screws, bolts, nuts, washers etc. is being supported by specialist expert stocking distributors like Challenge Europe.

Challenge Europe invite any company experiencing supply difficulties on these items, to contact them for an urgent service.

Further information on Challenge Europe products can be found on their website – www.challenge-europe.co.uk.

29/04/2020

Challenge Europe discuss the risks of reliance on the automatic specification selection feature in CAD systems

Challenge Europe come across the risks of excessive reliance on the automatic specification selection feature in many CAD systems at the design stage. These systems match physical dimensions but frequently neglect the materials or stock availability. This is also the case where, for example, a standardised component is requested, but in a material not covered by that standard. This focuses on the need to consult a specialist fastener supplier, especially regarding subcontract assemblies, since it may be that they cannot actually comply with the original drawing. In turn this has a major time implication in getting changes made when compliance is impossible.

A good example is a case where it was found necessary to take a superior product and downgrade it at extra cost, e.g. a washer to a certain specification, custom specified with a wide manufacturing tolerance where actually a normal spec washer would have been suitable but not meet the spec. The solution was to take standard washers and drill them out at extra cost. Especially where small quantities are concerned, this can be a major issue.

The solution has been found to lie in developing trusted supplier relationships where consultation at an early stage can bring these issues to light. Not only will such a supplier have an extensive knowledge of materials and finishes – they will also be in a position to advise on stock availability and alternative ways of meeting custom requirements. For example, it may not be necessary to custom produce from scratch where a standard item with treatment or other adaptation may be suitable, more readily available and cheaper.

Further information on Challenge Europe products can be found on their website – www.challenge-europe.co.uk.

A good example is a case where it was found necessary to take a superior product and downgrade it at extra cost, e.g. a washer to a certain specification, custom specified with a wide manufacturing tolerance where actually a normal spec washer would have been suitable but not meet the spec. The solution was to take standard washers and drill them out at extra cost. Especially where small quantities are concerned, this can be a major issue.

The solution has been found to lie in developing trusted supplier relationships where consultation at an early stage can bring these issues to light. Not only will such a supplier have an extensive knowledge of materials and finishes – they will also be in a position to advise on stock availability and alternative ways of meeting custom requirements. For example, it may not be necessary to custom produce from scratch where a standard item with treatment or other adaptation may be suitable, more readily available and cheaper.

Further information on Challenge Europe products can be found on their website – www.challenge-europe.co.uk.

20/03/2020

Ex-stock and custom Machine Screws – Challenge Europe discuss their future

Machine Screws represent a technology that is now conventional, so that Challenge Europe believe it is interesting to ask “what is their future?”

We have already seen many developments in drives/head configurations for automated production such as Hex drives and other socket screws, leading on to the more modern Phillips, Pozi and star drives, e.g. TORX, developed with a view to self-centring so that they will sustain torque loadings of automatic drives and with the further aim of being self-aligning when inserted.

We already have in the market an extensive selection of different thread pitches/multiple thread screws – custom screws – many diameters and head styles. Including threads for different materials such as steel, soft metals, plastics, zinc die castings, aluminium castings and so on.

More sophisticated driver forms can now be readily produced with advanced production machinery, leading to a great variety of head forms for differing purposes, e.g. wafer heads – thin and large diameter to spread the load over the substrate, which may be a thin sheet or soft material.

Other common forms include Narrow/small dia heads for confined spaces, Dome heads for aesthetics, Countersunk heads for smooth surfaces, Vandal-resistant heads for security, Integral washers, Pre-assembled sealing washers, Load spreading heads and Anti-vibration, e.g. serrated flanges.

Generally, in the future we foresee evolution rather than revolution with major market trends focused on:

- Better production technologies leading to better quality, greater accuracy, cleaner execution, reduced wastage, lower cost.

- Higher performance through use of higher spec materials, better finishes, superior insertion and drive capabilities, coupled with development of new thread forms to suit different materials and applications.

As discussed elsewhere, new thread forms are in development, but do not seem to have mass market utility as yet.

This has been the story of machine screws so far and we can only see it continuing as new industries of personal transit, renewable energy and recycling continue to develop new requirements with ever-lower energy use.

Clearly the threaded fastener industry continues to be vibrant with evolutionary growth based on their simple functionality at low cost.

Further information on Machine Screws from Challenge Europe can be found at www.challenge-europe.co.uk/threaded-products-screws/

We have already seen many developments in drives/head configurations for automated production such as Hex drives and other socket screws, leading on to the more modern Phillips, Pozi and star drives, e.g. TORX, developed with a view to self-centring so that they will sustain torque loadings of automatic drives and with the further aim of being self-aligning when inserted.

We already have in the market an extensive selection of different thread pitches/multiple thread screws – custom screws – many diameters and head styles. Including threads for different materials such as steel, soft metals, plastics, zinc die castings, aluminium castings and so on.

More sophisticated driver forms can now be readily produced with advanced production machinery, leading to a great variety of head forms for differing purposes, e.g. wafer heads – thin and large diameter to spread the load over the substrate, which may be a thin sheet or soft material.

Other common forms include Narrow/small dia heads for confined spaces, Dome heads for aesthetics, Countersunk heads for smooth surfaces, Vandal-resistant heads for security, Integral washers, Pre-assembled sealing washers, Load spreading heads and Anti-vibration, e.g. serrated flanges.

Generally, in the future we foresee evolution rather than revolution with major market trends focused on:

- Better production technologies leading to better quality, greater accuracy, cleaner execution, reduced wastage, lower cost.

- Higher performance through use of higher spec materials, better finishes, superior insertion and drive capabilities, coupled with development of new thread forms to suit different materials and applications.

As discussed elsewhere, new thread forms are in development, but do not seem to have mass market utility as yet.

This has been the story of machine screws so far and we can only see it continuing as new industries of personal transit, renewable energy and recycling continue to develop new requirements with ever-lower energy use.

Clearly the threaded fastener industry continues to be vibrant with evolutionary growth based on their simple functionality at low cost.

Further information on Machine Screws from Challenge Europe can be found at www.challenge-europe.co.uk/threaded-products-screws/

09/03/2020

Challenge Europe discuss the future for Imperial and Metric Screws

Sorting out the multiplicity of screw thread designs has been such a big issue for so long that there are lots of guides to give approximate conversions, although naturally there are no actual like-for-like equivalents. The team at Challenge Europe recently discussed a little history and some future-gazing.

Imperial threads - as it may be expected come out of the ins./feet standard developed in the blossoming of the industrial revolution when Imperial meant British Empire and then into the dynamic drive for mass production seen in the USA. These imperial threads were in their heyday at the end of that era which was approximately in the early part of the 20th century. When the Empire broke up under the stresses of two world wars and the rise of international power blocs together with demands for independence they continued in general use since the momentum of these newly grown industries carried them forward. Metric on the other hand comes from the millimetre/centimetre measurement system so popularised by Napoleon in the continental European theatre and subsequently established in the rebuilding and regrowth of the European manufacturing industries after the devastation of the wars that took place there.

They are not mutually compatible of course but may have approximate size replacements. The two standards essentially run alongside each other with metric (ISO) being the one that is replacing imperial across the world – it is the defacto global standard.

Consequently, metric screws are more readily available, e.g. ex-stock, more standard sizes, more easily sourced, more development in new products, more widely used and continuing to replace imperial globally on new projects. Challenge Europe are one of the few specialists who stock both standards in depth.

Increasingly tool kits are solely metric – although even today new spanners, taps and dies are available for Whitworth and BA – but are expensive so that they are often sourced by hobbyists and renovators as second hand items at auctions and car boot sales.

Since Imperial standards derive from the early days of the industrial revolution and industries like ship building and armaments that were important to the days of Empire and grew immensely at that time.

The first national standard was Whitworth - devised and specified by Joseph Whitworth in 1841. Followed by William Sellers who developed the Sellers thread of 1868 later developed into American Standard coarse and fine.

Well known to instrument and model makers is the British Association screw thread standard – known as BA these are small screws with the largest being OBA = 6mm dia. There continues to be a low level demand for older applications, e.g. old instruments – or for rebuilding of older vehicles.

Many countries have run both types alongside each other but all are in the process of moving to ISO metric standards if they have not already done so. The USA has probably held out longest due to the inertia of its huge market, but globalisation has led to sourcing of cheaper metric products for mass production and this has driven the conversion. The US/American market is therefore becoming more restricted - imperial products used to be the mainstay of general sales in the US, but not so now as US customers are more comfortable with metric specs. Availability of metric equipment in the US has now completely overtaken imperial screws in a relatively short time – roughly coinciding with the rise of Chinese manufacturing as the component supplier to the world.

New thread design development continues as specialist companies and engineering enthusiasts seek to explore niche areas, for example, “total surface contact” and bone screw fasteners – which may one day find application outside the medical/surgical field.

One particularly interesting arena is that of alignment correction whereby a misaligned screw will self-correct and pull itself back to its true axis.

Further developments are aimed at improving the performance of screws subjected to transverse loads which can lead to self-loosening or fatigue failure.

However, in the mass manufacturing market we do not at present see any further new thread designs on the horizon since metric forms seem to have adapted well to all general requirements. Elsewhere, other designs of fastener have been extensively developed from push-fit plumbing connectors to pop-in electrical and electronic fittings and this approach to specialist fastenings has very much taken off as a new way of dealing with often completely new problems.

While the transition from “old” to “new” thread forms is almost complete and many threaded fasteners have simply not been specified where they might previously – because now more cost-efficient fasteners of specialised design are available. However, it does seem that pockets of demand for imperial threads will continue for a long time yet.

Further information on Challenge Europe products can be found on th

Imperial threads - as it may be expected come out of the ins./feet standard developed in the blossoming of the industrial revolution when Imperial meant British Empire and then into the dynamic drive for mass production seen in the USA. These imperial threads were in their heyday at the end of that era which was approximately in the early part of the 20th century. When the Empire broke up under the stresses of two world wars and the rise of international power blocs together with demands for independence they continued in general use since the momentum of these newly grown industries carried them forward. Metric on the other hand comes from the millimetre/centimetre measurement system so popularised by Napoleon in the continental European theatre and subsequently established in the rebuilding and regrowth of the European manufacturing industries after the devastation of the wars that took place there.

They are not mutually compatible of course but may have approximate size replacements. The two standards essentially run alongside each other with metric (ISO) being the one that is replacing imperial across the world – it is the defacto global standard.

Consequently, metric screws are more readily available, e.g. ex-stock, more standard sizes, more easily sourced, more development in new products, more widely used and continuing to replace imperial globally on new projects. Challenge Europe are one of the few specialists who stock both standards in depth.

Increasingly tool kits are solely metric – although even today new spanners, taps and dies are available for Whitworth and BA – but are expensive so that they are often sourced by hobbyists and renovators as second hand items at auctions and car boot sales.

Since Imperial standards derive from the early days of the industrial revolution and industries like ship building and armaments that were important to the days of Empire and grew immensely at that time.

The first national standard was Whitworth - devised and specified by Joseph Whitworth in 1841. Followed by William Sellers who developed the Sellers thread of 1868 later developed into American Standard coarse and fine.

Well known to instrument and model makers is the British Association screw thread standard – known as BA these are small screws with the largest being OBA = 6mm dia. There continues to be a low level demand for older applications, e.g. old instruments – or for rebuilding of older vehicles.

Many countries have run both types alongside each other but all are in the process of moving to ISO metric standards if they have not already done so. The USA has probably held out longest due to the inertia of its huge market, but globalisation has led to sourcing of cheaper metric products for mass production and this has driven the conversion. The US/American market is therefore becoming more restricted - imperial products used to be the mainstay of general sales in the US, but not so now as US customers are more comfortable with metric specs. Availability of metric equipment in the US has now completely overtaken imperial screws in a relatively short time – roughly coinciding with the rise of Chinese manufacturing as the component supplier to the world.

New thread design development continues as specialist companies and engineering enthusiasts seek to explore niche areas, for example, “total surface contact” and bone screw fasteners – which may one day find application outside the medical/surgical field.

One particularly interesting arena is that of alignment correction whereby a misaligned screw will self-correct and pull itself back to its true axis.

Further developments are aimed at improving the performance of screws subjected to transverse loads which can lead to self-loosening or fatigue failure.

However, in the mass manufacturing market we do not at present see any further new thread designs on the horizon since metric forms seem to have adapted well to all general requirements. Elsewhere, other designs of fastener have been extensively developed from push-fit plumbing connectors to pop-in electrical and electronic fittings and this approach to specialist fastenings has very much taken off as a new way of dealing with often completely new problems.

While the transition from “old” to “new” thread forms is almost complete and many threaded fasteners have simply not been specified where they might previously – because now more cost-efficient fasteners of specialised design are available. However, it does seem that pockets of demand for imperial threads will continue for a long time yet.

Further information on Challenge Europe products can be found on th

24/02/2020

Challenge Europe announce manufacturing partnerships for threaded fasteners

At a time when reshoring is very much a topic of concern, Challenge Europe are delighted to announce their partnership capabilities for sourcing and supply chain management of threaded fasteners on a specialist basis. This covers threaded products and related items from screws and bolts to nuts, washers, security fasteners, inserts and custom fasteners.

Challenge Europe are able to partner with assemblers/manufacturers where they offer contributions to cost control and pricing strategies by minimising administration costs, achieved by applying experience and appropriate technology, e.g. VMI. This enables them to deploy pay-as-you-use charging so reducing customer inventory costs to spread cash flow and by dealing with environmental issues to minimise the impact of manufacturing processes.

In addition to ex-stock programmed supply Challenge Europe assist partners by responding to urgent or short-term custom manufacturing of fasteners from their own in-house facility. This capability is ideal for small quantities and extends to partnering arrangements with fabricators and finishers so that they can cover a wide range of items from specialist threaded fasteners to sheet metal or cast fixings.

This capability enables them to produce components from alternative materials at short notice and to incorporate them into packaged sub-assemblies which allows customers to gain a complete package of high-quality and low-cost on standard mass-produced items and on small quantity specialist components.

A typical specialist partnership may therefore include in-house machining coupled with a global sourcing and supply infrastructure supported by their in-depth expertise of the manufacturing cycle gained from over 30 years in the engineering arena.

Further information on Challenge Europe partnership capabilities can be found at www.challenge-europe.co.uk/service-packages/.

Challenge Europe are able to partner with assemblers/manufacturers where they offer contributions to cost control and pricing strategies by minimising administration costs, achieved by applying experience and appropriate technology, e.g. VMI. This enables them to deploy pay-as-you-use charging so reducing customer inventory costs to spread cash flow and by dealing with environmental issues to minimise the impact of manufacturing processes.

In addition to ex-stock programmed supply Challenge Europe assist partners by responding to urgent or short-term custom manufacturing of fasteners from their own in-house facility. This capability is ideal for small quantities and extends to partnering arrangements with fabricators and finishers so that they can cover a wide range of items from specialist threaded fasteners to sheet metal or cast fixings.

This capability enables them to produce components from alternative materials at short notice and to incorporate them into packaged sub-assemblies which allows customers to gain a complete package of high-quality and low-cost on standard mass-produced items and on small quantity specialist components.

A typical specialist partnership may therefore include in-house machining coupled with a global sourcing and supply infrastructure supported by their in-depth expertise of the manufacturing cycle gained from over 30 years in the engineering arena.

Further information on Challenge Europe partnership capabilities can be found at www.challenge-europe.co.uk/service-packages/.

20/02/2020

Self-drilling/self-tapping screws stocked in depth for metals and plastics at Challenge Europe

Self-drilling/self-tapping screws for metals and plastics – ex-stock from Challenge Europe are often used in the construction industry, e.g. for fixing sheet metal in place on frameworks and can come with bonded washers to prevent water ingress in outdoor applications. Self-drilling screws come in a variety of formats but all are based upon the principle of drilling and tapping in one operation. They are generally used in steel, softer metals or plastics and there is a range specially designed for use in wood/composite materials.

Major benefits in using this type of fastening include increased speed of installation and efficiency provided by combining the drilling and tapping operations as well as a functional improvement in alignment, which otherwise could require re-setting the screw for correct fitment.

Self-tapping screws are stocked in depth as hardened and plated carbon steel and stainless steel self-tappers for use mainly in sheet steel products. These screws form or tap their own thread so saving time and providing a strong clamping action with the ability to remove and replace if required. Countersunk, Pan, and Flange heads are commonly available, the flange head having the advantage of spreading the load well and minimising deformation of the sheet thus eliminating the need for an under head washer. The traditional slotted drive is still available, but the modern preference is for cross recessed or multi-splined (star) drives to suit modern insertion equipment. Self-drilling and self-tapping screws are available in plated steel and stainless steel for engineering, construction and general assembly purposes.

Specialist Construction screws are often thought of as a separate genre but principally operate in the same way as their more standard cousins and tend to be designed to perform more specific functions. These functions range from having integrated sealing washers, for the fixing of cladding, through to Bugle head designs for use in fixing plasterboard. There are a variety of drives available, often linked to the intended function of the fixing, and can include designs such as Hex, Star, Pozi, Phillips and even Square. Some fixings are available in a Collated format where speed and handling is important.

Largely because of their wide utility this group of self-drilling/self-tapping screws offer an extensive range of different head and drive types. Head types include the following and may often be specified with a drive configuration of choice:

- Pan head: which has a thick rounded, outer top with a large surface area

- Button or dome head: which is cylindrical head with a dome shaped top

- Countersunk or flat head: An inverted cone head with a flat outer surface

- Raised countersunk head: Combines a countersunk head with a rounded upper surface for decorative purposes

- Bugle head: which presents a smooth increasing transition from the shank to the angle of the head

- Flanged head: Can be any head style incorporating an integrated flange so that it does not require a washer

Also wafer head – which is very thin – for use where a low profile is required.

In some instances they can also be offered with anti-vandal features, such as pin hexagon, pin star (multi-splined) and clutch head.

Further information on self-drilling/self-tapping screws from Challenge Europe can be found at www.challenge-europe.co.uk/threaded-products-screws/.

Major benefits in using this type of fastening include increased speed of installation and efficiency provided by combining the drilling and tapping operations as well as a functional improvement in alignment, which otherwise could require re-setting the screw for correct fitment.

Self-tapping screws are stocked in depth as hardened and plated carbon steel and stainless steel self-tappers for use mainly in sheet steel products. These screws form or tap their own thread so saving time and providing a strong clamping action with the ability to remove and replace if required. Countersunk, Pan, and Flange heads are commonly available, the flange head having the advantage of spreading the load well and minimising deformation of the sheet thus eliminating the need for an under head washer. The traditional slotted drive is still available, but the modern preference is for cross recessed or multi-splined (star) drives to suit modern insertion equipment. Self-drilling and self-tapping screws are available in plated steel and stainless steel for engineering, construction and general assembly purposes.

Specialist Construction screws are often thought of as a separate genre but principally operate in the same way as their more standard cousins and tend to be designed to perform more specific functions. These functions range from having integrated sealing washers, for the fixing of cladding, through to Bugle head designs for use in fixing plasterboard. There are a variety of drives available, often linked to the intended function of the fixing, and can include designs such as Hex, Star, Pozi, Phillips and even Square. Some fixings are available in a Collated format where speed and handling is important.

Largely because of their wide utility this group of self-drilling/self-tapping screws offer an extensive range of different head and drive types. Head types include the following and may often be specified with a drive configuration of choice:

- Pan head: which has a thick rounded, outer top with a large surface area

- Button or dome head: which is cylindrical head with a dome shaped top

- Countersunk or flat head: An inverted cone head with a flat outer surface

- Raised countersunk head: Combines a countersunk head with a rounded upper surface for decorative purposes

- Bugle head: which presents a smooth increasing transition from the shank to the angle of the head

- Flanged head: Can be any head style incorporating an integrated flange so that it does not require a washer

Also wafer head – which is very thin – for use where a low profile is required.

In some instances they can also be offered with anti-vandal features, such as pin hexagon, pin star (multi-splined) and clutch head.

Further information on self-drilling/self-tapping screws from Challenge Europe can be found at www.challenge-europe.co.uk/threaded-products-screws/.

11/02/2020

The Challenge Europe difference between Thread-forming screws and Self-tappers

Challenge Europe are delighted to hold in stock both metal thread-forming screws, e.g. for castings etc where they secure components by forming a machine thread – also purpose designed screws for thread forming in plastics.

The Challenge Europe team point out that thread forming tri-lobular screws are used for fixing into metal components – a form of self-tapping screw, they use the tougher tri-lobular design which assists the grain flow as it effectively deforms a thread into thicker material than could be managed with a standard self-tapping screw. This process results in a thread geometry that is more accurate than a standard self-tapper and so provides a stronger fixing which is more resistant to loosening under vibration. Almost a machine screw in concept these thread forming screws leave a tapped hole when removed and may be replaced with a standard rolled thread machine screw if required – for example at servicing or repair and thereby provide a much higher torque loading capacity than a standard self-tapping thread. They are typically used in steel, aluminium, aluminium die castings, zinc die castings, magnesium and other light alloys.

Heads and drives include countersunk, pan, and hexagonal/flange types with cross recess, multi-splined (star) or hexagonal formats. Hardened steel is normal for most applications and is suitable for use in a variety of metals providing the correct diameter pilot holes are in situ. Stainless steel thread forming screws are also freely available but tend to be used in softer materials such as aluminium and zinc.

Thread forming screws for plastics have become more and more important in the assembly of everything from electronic equipment to furniture, as they are easily inserted into drilled or moulded holes in thermoplastic materials where they deform the material to provide optimum fastening force superior to standard self-tappers. Thread forming screws are especially useful in the manufacturing production environment where an automatic feed can be employed to greatly speed the assembly process, by eliminating the need for nuts or inserts, so reducing piece part costs, labour costs and process costs.

There are a range of thread geometries associated with this type of screw, this is to allow for their use with different component materials and design features. For example, if required for insertion into thinner walled, harder plastic mouldings it might be advisable to try a tri-lobular thread variant which tends to reduce the risk of burst out. Of course, the choice of hole diameter can be critical and the team at Challenge can advise on both screw selection and suitable hole diameters.

Head formats for use with plastics include countersunk, pan, and flange types with cross recess or multi-splined (star) drives. Typical materials include hardened steel with a zinc & clear passivate finish or in some instances black finishes can be available, also stainless steel. Again, proper installation requires a pre-formed hole of the right diameter to properly form or cut the right size thread and to take advantage of the benefits of this design which include low radial stress, no material to jam the thread, maximum resistance to substrate relaxation and no material stress through plastification.

Further information on Challenge Europe products can be found on their website – www.challenge-europe.co.uk.

The Challenge Europe team point out that thread forming tri-lobular screws are used for fixing into metal components – a form of self-tapping screw, they use the tougher tri-lobular design which assists the grain flow as it effectively deforms a thread into thicker material than could be managed with a standard self-tapping screw. This process results in a thread geometry that is more accurate than a standard self-tapper and so provides a stronger fixing which is more resistant to loosening under vibration. Almost a machine screw in concept these thread forming screws leave a tapped hole when removed and may be replaced with a standard rolled thread machine screw if required – for example at servicing or repair and thereby provide a much higher torque loading capacity than a standard self-tapping thread. They are typically used in steel, aluminium, aluminium die castings, zinc die castings, magnesium and other light alloys.

Heads and drives include countersunk, pan, and hexagonal/flange types with cross recess, multi-splined (star) or hexagonal formats. Hardened steel is normal for most applications and is suitable for use in a variety of metals providing the correct diameter pilot holes are in situ. Stainless steel thread forming screws are also freely available but tend to be used in softer materials such as aluminium and zinc.

Thread forming screws for plastics have become more and more important in the assembly of everything from electronic equipment to furniture, as they are easily inserted into drilled or moulded holes in thermoplastic materials where they deform the material to provide optimum fastening force superior to standard self-tappers. Thread forming screws are especially useful in the manufacturing production environment where an automatic feed can be employed to greatly speed the assembly process, by eliminating the need for nuts or inserts, so reducing piece part costs, labour costs and process costs.

There are a range of thread geometries associated with this type of screw, this is to allow for their use with different component materials and design features. For example, if required for insertion into thinner walled, harder plastic mouldings it might be advisable to try a tri-lobular thread variant which tends to reduce the risk of burst out. Of course, the choice of hole diameter can be critical and the team at Challenge can advise on both screw selection and suitable hole diameters.

Head formats for use with plastics include countersunk, pan, and flange types with cross recess or multi-splined (star) drives. Typical materials include hardened steel with a zinc & clear passivate finish or in some instances black finishes can be available, also stainless steel. Again, proper installation requires a pre-formed hole of the right diameter to properly form or cut the right size thread and to take advantage of the benefits of this design which include low radial stress, no material to jam the thread, maximum resistance to substrate relaxation and no material stress through plastification.

Further information on Challenge Europe products can be found on their website – www.challenge-europe.co.uk.

07/02/2020

Difference Between Thread-Forming Screws And Self-Tappers

Challenge Europe has shed some light on the difference between metal thread-forming screws and purpose designed screws for thread forming in plastics - both which are stocked by the company.

The team points out that thread forming tri-lobular screws are used for fixing into metal components – a form of self-tapping screw, they use the tougher tri-lobular design which assists the grain flow as it effectively deforms a thread into thicker material than could be managed with a standard self-tapping screw. This process results in a thread geometry that is more accurate than a standard self-tapper and so provides a stronger fixing which is more resistant to loosening under vibration. Almost a machine screw in concept these thread forming screws leave a tapped hole when removed and may be replaced with a standard rolled thread machine screw if required – for example at servicing or repair and thereby provide a much higher torque loading capacity than a standard self-tapping thread. They are typically used in steel, aluminium, aluminium die castings, zinc die castings, magnesium and other light alloys.

hss

Heads and drives include countersunk, pan, and hexagonal/flange types with cross recess, multi-splined (star) or hexagonal formats. Hardened steel is normal for most applications and is suitable for use in a variety of metals providing the correct diameter pilot holes are in situ. Stainless steel thread forming screws are also freely available but tend to be used in softer materials such as aluminium and zinc.

Thread forming screws for plastics have become more and more important in the assembly of everything from electronic equipment to furniture, as they are easily inserted into drilled or moulded holes in thermoplastic materials where they deform the material to provide optimum fastening force superior to standard self-tappers. Thread forming screws are especially useful in the manufacturing production environment where an automatic feed can be employed to greatly speed the assembly process, by eliminating the need for nuts or inserts, so reducing piece part costs, labour costs and process costs.

There are a range of thread geometries associated with this type of screw, this is to allow for their use with different component materials and design features. For example, if required for insertion into thinner walled, harder plastic mouldings it might be advisable to try a tri-lobular thread variant which tends to reduce the risk of burst out. Of course, the choice of hole diameter can be critical and the team at Challenge can advise on both screw selection and suitable hole diameters.

Head formats for use with plastics include countersunk, pan, and flange types with cross recess or multi-splined (star) drives. Typical materials include hardened steel with a zinc & clear passivate finish or in some instances black finishes can be available, also stainless steel. Again, proper installation requires a pre-formed hole of the right diameter to properly form or cut the right size thread and to take advantage of the benefits of this design which include low radial stress, no material to jam the thread, maximum resistance to substrate relaxation and no material stress through plastification.

The team points out that thread forming tri-lobular screws are used for fixing into metal components – a form of self-tapping screw, they use the tougher tri-lobular design which assists the grain flow as it effectively deforms a thread into thicker material than could be managed with a standard self-tapping screw. This process results in a thread geometry that is more accurate than a standard self-tapper and so provides a stronger fixing which is more resistant to loosening under vibration. Almost a machine screw in concept these thread forming screws leave a tapped hole when removed and may be replaced with a standard rolled thread machine screw if required – for example at servicing or repair and thereby provide a much higher torque loading capacity than a standard self-tapping thread. They are typically used in steel, aluminium, aluminium die castings, zinc die castings, magnesium and other light alloys.

hss

Heads and drives include countersunk, pan, and hexagonal/flange types with cross recess, multi-splined (star) or hexagonal formats. Hardened steel is normal for most applications and is suitable for use in a variety of metals providing the correct diameter pilot holes are in situ. Stainless steel thread forming screws are also freely available but tend to be used in softer materials such as aluminium and zinc.

Thread forming screws for plastics have become more and more important in the assembly of everything from electronic equipment to furniture, as they are easily inserted into drilled or moulded holes in thermoplastic materials where they deform the material to provide optimum fastening force superior to standard self-tappers. Thread forming screws are especially useful in the manufacturing production environment where an automatic feed can be employed to greatly speed the assembly process, by eliminating the need for nuts or inserts, so reducing piece part costs, labour costs and process costs.

There are a range of thread geometries associated with this type of screw, this is to allow for their use with different component materials and design features. For example, if required for insertion into thinner walled, harder plastic mouldings it might be advisable to try a tri-lobular thread variant which tends to reduce the risk of burst out. Of course, the choice of hole diameter can be critical and the team at Challenge can advise on both screw selection and suitable hole diameters.

Head formats for use with plastics include countersunk, pan, and flange types with cross recess or multi-splined (star) drives. Typical materials include hardened steel with a zinc & clear passivate finish or in some instances black finishes can be available, also stainless steel. Again, proper installation requires a pre-formed hole of the right diameter to properly form or cut the right size thread and to take advantage of the benefits of this design which include low radial stress, no material to jam the thread, maximum resistance to substrate relaxation and no material stress through plastification.

16/01/2020

Challenge Europe announce ex-stock star/multi-splined (TORX) drive screws

Challenge Europe are pleased to offer ex-stock Hexalobular Internal Drive screws (generically of the TORX style) as part of their manufacturing supply service for delivery under normal production protocols, e.g. Lineside supply, JIT, Kanban or similar.

Often referred to as star drive or multi-splined screws, they are available in metric standard sizes and are designed for automation assembly in that they feature a positive drive with reduced slip-out and are especially suitable for controlled torque insertion - using bowl feed equipment.

Hexalobular Internal Drive screws are popular for use in the auto, motorcycle and bicycle industries, as well as instrumentation, electronics, computers, brown goods and construction projects.

A wide range of screw types in steel and stainless steel are now available with this type of recess to ISO 10664.

Security or tamper-resistant variants are available with centre pin requiring a special driver – also external Multi-splined bolt heads are available providing many of the benefits associated with the aforementioned internal drive version.

Further information on Hexalobular Internal Drive screws from Challenge Europe can be found at www.challenge-europe.co.uk/hexalobular-drive-screws/.

Often referred to as star drive or multi-splined screws, they are available in metric standard sizes and are designed for automation assembly in that they feature a positive drive with reduced slip-out and are especially suitable for controlled torque insertion - using bowl feed equipment.

Hexalobular Internal Drive screws are popular for use in the auto, motorcycle and bicycle industries, as well as instrumentation, electronics, computers, brown goods and construction projects.

A wide range of screw types in steel and stainless steel are now available with this type of recess to ISO 10664.

Security or tamper-resistant variants are available with centre pin requiring a special driver – also external Multi-splined bolt heads are available providing many of the benefits associated with the aforementioned internal drive version.

Further information on Hexalobular Internal Drive screws from Challenge Europe can be found at www.challenge-europe.co.uk/hexalobular-drive-screws/.

04/12/2019

Socket Head Screws from Challenge Europe

Ex-stock production supply specialists Challenge Europe are pleased to offer five types of socket screws from stock to support the engineering/assembly industries.

Socket head cap screws, socket shoulder screws, socket button head screws, socket countersunk screws and socket setscrews are all in common usage by virtue of their ease of use in the production environment and for their very clean aesthetic appearance.

The great strength of these screws makes them popular in specialist tooling, engineering assemblies, hydraulic systems, vehicle production, furniture and other high quality technical equipment.

Further information on socket head screws from Challenge Europe can be found at www.challenge-europe.co.uk/socket-products-screws-and-bolts/.

Socket head cap screws, socket shoulder screws, socket button head screws, socket countersunk screws and socket setscrews are all in common usage by virtue of their ease of use in the production environment and for their very clean aesthetic appearance.

The great strength of these screws makes them popular in specialist tooling, engineering assemblies, hydraulic systems, vehicle production, furniture and other high quality technical equipment.

Further information on socket head screws from Challenge Europe can be found at www.challenge-europe.co.uk/socket-products-screws-and-bolts/.

01/11/2019

Challenge Europe - service packages - the most important component in manufacturing

Challenge Europe are delighted to offer a fastener sourcing and supply chain service to manufacturing design and production engineers and consider that taken overall such a service package may well be the most important component in that process.

We can all recognise that the specification of a fastener will be governed by a number of possibly conflicting factors. At the concept/design stage, the designer will consider the functionality of the components, environmental issues, life-cycle expectancy, how the assembly is to be held together and whether there is a need to disassemble it amongst other concerns. For the sake of simplicity and cost the first consideration is to see if standard fasteners can be used and check the current availability with suppliers.

Whilst International Standards will provide comprehensive information on things like fastener diameters, lengths, materials etc., we should not assume that the entire range listed in a particular Standard will be available from stock as standard product range – so even “standard” fasteners may require specialist sourcing and supply arrangements.

Consideration of standards is of course vital and can be difficult without guidance from an experienced team - the following are common examples:

- International Organisation for Standardisation (ISO) – ISO Metric Threads

- Deutches Institut für Normung (DIN) – ISO Metric Threads

- American National Standards Institute (ANSI) – Unified National and Metric Threads

- British Standards Institution (BSI) – ISO Metric, Unified National and British Threads

Reference to these international standards will provide detailed specifications for thread tolerances and other information on the geometry of fastener threads while considerations of other configuration requirements can be integrated in the final design.

Drive types will need to be considered where quantity, speed, torque requirements and cost can be defining factors, differentiating between slotted, Phillips, Pozi and Torx to name a few well-known variants.

The team at Challenge Europe can offer guidance on material selection based on cost, product strength characteristics, environmental and corrosion-resistance requirements, application of the fastened joint. They will of course include steel; stainless steel – Austenitic, Ferritic or Martensitic; plus, brass, bronze, aluminium, copper and plastics of many sorts.

The actual manufacturing processes, heat treatments or annealing processes involved in the production of a suitable fastener will very likely have a profound influence on the quality and longevity of the final assembly and so form part of consideration in the service package.

Once the sourcing is confirmed only then can supply chain issues be addressed such as stocking, importing, batch sizes, delivery, e.g. using JIT, Lineside supply, VMI, Kanban or other protocols.

Further information on service packages available from Challenge Europe products can be found at www.challenge-europe.co.uk/service-packages/.

We can all recognise that the specification of a fastener will be governed by a number of possibly conflicting factors. At the concept/design stage, the designer will consider the functionality of the components, environmental issues, life-cycle expectancy, how the assembly is to be held together and whether there is a need to disassemble it amongst other concerns. For the sake of simplicity and cost the first consideration is to see if standard fasteners can be used and check the current availability with suppliers.

Whilst International Standards will provide comprehensive information on things like fastener diameters, lengths, materials etc., we should not assume that the entire range listed in a particular Standard will be available from stock as standard product range – so even “standard” fasteners may require specialist sourcing and supply arrangements.

Consideration of standards is of course vital and can be difficult without guidance from an experienced team - the following are common examples:

- International Organisation for Standardisation (ISO) – ISO Metric Threads

- Deutches Institut für Normung (DIN) – ISO Metric Threads

- American National Standards Institute (ANSI) – Unified National and Metric Threads

- British Standards Institution (BSI) – ISO Metric, Unified National and British Threads

Reference to these international standards will provide detailed specifications for thread tolerances and other information on the geometry of fastener threads while considerations of other configuration requirements can be integrated in the final design.

Drive types will need to be considered where quantity, speed, torque requirements and cost can be defining factors, differentiating between slotted, Phillips, Pozi and Torx to name a few well-known variants.

The team at Challenge Europe can offer guidance on material selection based on cost, product strength characteristics, environmental and corrosion-resistance requirements, application of the fastened joint. They will of course include steel; stainless steel – Austenitic, Ferritic or Martensitic; plus, brass, bronze, aluminium, copper and plastics of many sorts.

The actual manufacturing processes, heat treatments or annealing processes involved in the production of a suitable fastener will very likely have a profound influence on the quality and longevity of the final assembly and so form part of consideration in the service package.

Once the sourcing is confirmed only then can supply chain issues be addressed such as stocking, importing, batch sizes, delivery, e.g. using JIT, Lineside supply, VMI, Kanban or other protocols.

Further information on service packages available from Challenge Europe products can be found at www.challenge-europe.co.uk/service-packages/.

17/10/2019

Custom Nuts - Challenge Europe provide the solution

Custom nuts from Challenge Europe meet many widely varying needs in materials such as steel, stainless steel, copper, brass, aluminium, plastic or exotics like titanium. There are many different styles on the market today. Amongst the commonest are the Full Nut, the Lock Nut (sometimes referred to as a Half-Nut or Thin Nut) and the Nylon Insert Self-Locking Nut.

Special shapes include curved combi-washers/collars to fit tubing etc., or castellated designs of varying pitch to allow for indexed adjustment. Options are almost endless, and the final choice is heavily dependent upon the service expectations required.

Essentially conceived as any piece of metal (or plastic) with a thread in it intended to be fixed to a component, special nuts can have C wrench slots, pin wrench holes, may be double-ended or welded (projection weld nut) to a foot plate or bracket. All metal self-locking nuts are available where higher temperatures are likely to be experienced. These include Aerotight, Philidas, Stover, Binx, Cleveloc and many others, all providing anti-vibration loosening characteristics.

Security (anti-vandal) nuts available include Kinmar, both permanent and removable, Tufnuts, Scroll Nuts and the ever-popular Shear Nut. Flange Nuts, both plain and serrated flange, fill another gap where load spreading is required without the need of a washer, while the serrated flange version also provides a degree of resistance to loosening under vibration. The Combi-Nut design is another configuration that provides load spreading where a washer is trapped into the nut but is free to rotate. Versions fitted with an external toothed shakeproof washer can also offer an element of resistance to vibration loosening.

The team at Challenge Europe are experienced in fabrication of custom nuts in-house or with trusted subcontractors against a program of supply chain demand for industrial manufacturing. Combined with a range of materials and finishes you pretty much have a nut for every occasion, meeting the demands across industries as diverse as lighting, electronics, general equipment, refuse processing, machine tools, conveyors and automated/specialist vehicles.

Further information on custom nuts from Challenge Europe can be found at www.challenge-europe.co.uk/nut-products/.

Special shapes include curved combi-washers/collars to fit tubing etc., or castellated designs of varying pitch to allow for indexed adjustment. Options are almost endless, and the final choice is heavily dependent upon the service expectations required.

Essentially conceived as any piece of metal (or plastic) with a thread in it intended to be fixed to a component, special nuts can have C wrench slots, pin wrench holes, may be double-ended or welded (projection weld nut) to a foot plate or bracket. All metal self-locking nuts are available where higher temperatures are likely to be experienced. These include Aerotight, Philidas, Stover, Binx, Cleveloc and many others, all providing anti-vibration loosening characteristics.

Security (anti-vandal) nuts available include Kinmar, both permanent and removable, Tufnuts, Scroll Nuts and the ever-popular Shear Nut. Flange Nuts, both plain and serrated flange, fill another gap where load spreading is required without the need of a washer, while the serrated flange version also provides a degree of resistance to loosening under vibration. The Combi-Nut design is another configuration that provides load spreading where a washer is trapped into the nut but is free to rotate. Versions fitted with an external toothed shakeproof washer can also offer an element of resistance to vibration loosening.

The team at Challenge Europe are experienced in fabrication of custom nuts in-house or with trusted subcontractors against a program of supply chain demand for industrial manufacturing. Combined with a range of materials and finishes you pretty much have a nut for every occasion, meeting the demands across industries as diverse as lighting, electronics, general equipment, refuse processing, machine tools, conveyors and automated/specialist vehicles.

Further information on custom nuts from Challenge Europe can be found at www.challenge-europe.co.uk/nut-products/.

01/10/2019

Custom Fasteners – a speciality from Challenge Europe from screws and bolts to formed and threaded rods

From some of the simplest and most commonly available fasteners such as the humble machine screw to the more specialised and often heavily customised bolt Challenge Europe can help in all formats. Threaded fasteners are perhaps uniquely adaptable since designs can readily be adjusted to suit many diverse applications requiring non-standard lengths, intermediate diameters as well as alternatives to the generally available materials of steel, stainless steel, brass, aluminium and nylon.

These alternate materials include titanium, copper, phosphor bronze, duplex and super duplex stainless steels. Threaded fasteners with special heads may be needed such as bar type (T form) to locate in slots, or bolts for special purposes, e.g. welded to a foot plate or spiked for use in materials processing machinery such as drums where replacement is often required.

A common form of specialist bolt is the U bolt or hook where the extended bolt can be formed in such a way as to create a completely different item of custom dimensions. Further refinement is then possible with varying surface treatments such as zinc and clear, chemi black or anodising.

It is truly remarkable how versatile the humble screw has become and how readily suppliers like Challenge Europe can create that special solution.

Further information on Challenge Europe products can be found on their website – www.challenge-europe.co.uk.

These alternate materials include titanium, copper, phosphor bronze, duplex and super duplex stainless steels. Threaded fasteners with special heads may be needed such as bar type (T form) to locate in slots, or bolts for special purposes, e.g. welded to a foot plate or spiked for use in materials processing machinery such as drums where replacement is often required.

A common form of specialist bolt is the U bolt or hook where the extended bolt can be formed in such a way as to create a completely different item of custom dimensions. Further refinement is then possible with varying surface treatments such as zinc and clear, chemi black or anodising.

It is truly remarkable how versatile the humble screw has become and how readily suppliers like Challenge Europe can create that special solution.

Further information on Challenge Europe products can be found on their website – www.challenge-europe.co.uk.

10/09/2019

Production, products and service – Kevin Moorcroft of Challenge Europe explains the nuts and bolts of successful manufacturing relationships