Time and date

CONSTRUCTION DIRECTORY

TSL Turton Contact Details

Contact

Doug Maxwell

Email

Address

Burton Road

Sheffield,

Sheffield,

Sheffield

South Yorkshire

S3 8DA

England, Uk

About TSL Turton

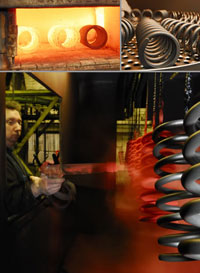

Making Springs For Industry

Our heritage in spring manufacture can be traced back as far as 1879. Our long history has provided us with a wealth of experience which, together with our investment in the future, ensures innovative solutions to meet customer needs both today and in the longer term.

We provide high specification springs including compression, extension, torsion, anti-roll bars and volute springs, manufactured to order for specialist requirements within industries such as automotive, mining, rail, oil & gas, agriculture and aerospace. Our range cover both hot and cold wound springs ranging from 1mm to 85mm diameter wire.

At TSL Turton we combine superior engineering expertise with outstanding service to provide the highest standard of spring available. Our involvement in the design process at an early stage ensures the most practical and efficient solution for any application.

TSL Turton is registered to ISO 9001-2008 and with our own rigorous in-house testing procedures we can guarantee the very best quality. Our procedures include regular Sub-contracted testing, Lock down testing, Load testing up to 100 tons, Surface finishing, Surface crack detection, Fatigue testing, Almen arc shotpeening, Elasticity testing, Hardness testing, Salt spray corrosion testing and Dimensional verification.

Operations

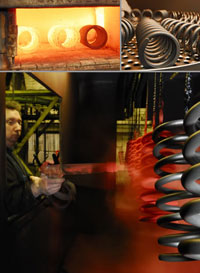

Our heritage in spring manufacture can be traced back as far as 1879. Our long history has provided us with a wealth of experience which, together with our investment in the future, ensures innovative solutions to meet customer needs both today and in the longer term.

We provide high specification springs including compression, extension, torsion, anti-roll bars and volute springs, manufactured to order for specialist requirements within industries such as automotive, mining, rail, oil & gas, agriculture and aerospace. Our range cover both hot and cold wound springs ranging from 1mm to 85mm diameter wire.

At TSL Turton we combine superior engineering expertise with outstanding service to provide the highest standard of spring available. Our involvement in the design process at an early stage ensures the most practical and efficient solution for any application.

TSL Turton is registered to ISO 9001-2008 and with our own rigorous in-house testing procedures we can guarantee the very best quality. Our procedures include regular Sub-contracted testing, Lock down testing, Load testing up to 100 tons, Surface finishing, Surface crack detection, Fatigue testing, Almen arc shotpeening, Elasticity testing, Hardness testing, Salt spray corrosion testing and Dimensional verification.

Operations