Time and date

CONSTRUCTION DIRECTORY

Operator Training Services Contact Details

Address

Ivy Mill Lane

Godstone

Surrey

RH9 8NR

England UK

Opening Hours

Tuesday

09:00-17:00

Monday

09:00-17:00

Tuesday

09:00-17:00

Wednesday

09:00-17:00

Thursday

09:00-17:00

Friday

09:00-17:00

Saturday

Closed

Sunday

Closed

Other Dates

About Operator Training Services

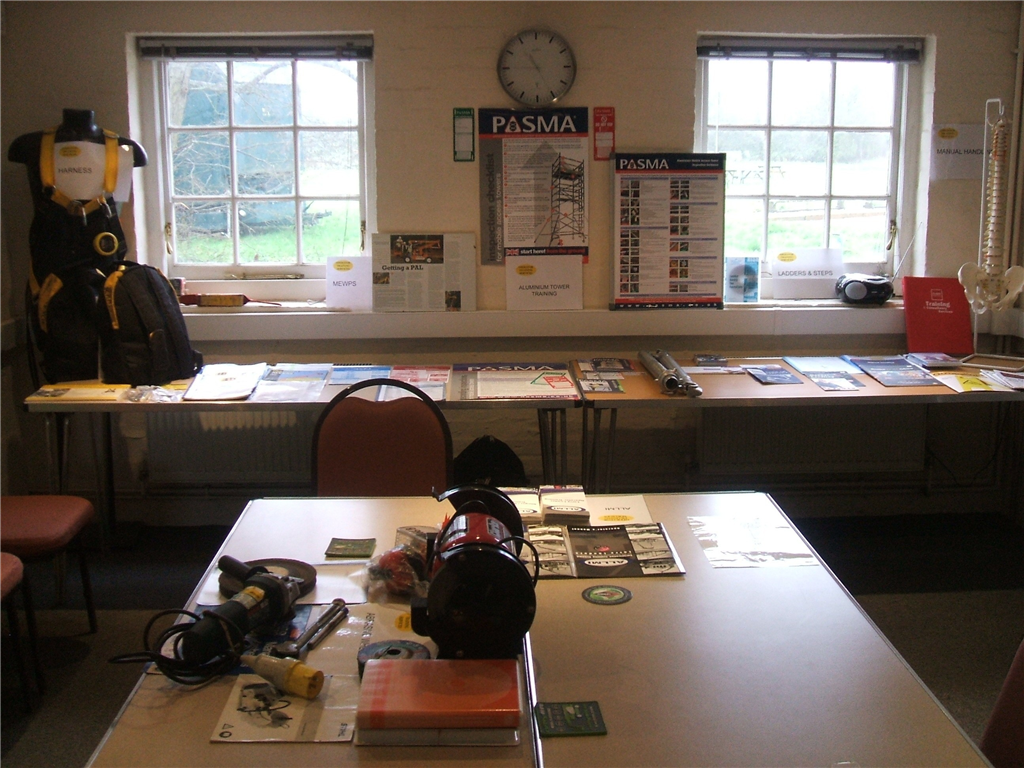

PASMA, IPAF and The Ladder Association Training Courses

Operator Training Services is a dedicated training company mainly specialising in Working At Height with the capacity to provide nationally recognised courses throughout the UK with IPAF, PASMA and The Ladder Association.

Our aim is to advance safety standards by instructing our delegates with the necessary knowledge to work safely and to the highest standards. OTS instructors can provide training extensively in the areas below, as they have a wealth of technical knowledge and practical experience. Our instructors, course content and premises are subject to thorough inspection by the Training Scheme Auditors.

IPAF Training Courses – (International Power Access Federation)

MEWP Operator/Demonstrator Training covering scissor lifts, self propelled booms (cherry pickers), vehicle mounted platforms and insulated aerial devices.

PASMA Training Courses – (Prefabricated Access Suppliers’ & Manufacturers’ Association) Mobile Access Tower, Work at Height (Essentials) and Low Level Training.

The Ladder Association – Ladder & Steps User and Inspector Training.

In addition, we can provide our own in-house training for manual handling, abrasive wheels, harnesses and safety awareness.

PASMA, IPAF and The Ladder Association Training can be provided at our training centres based in Ashford, Kent and Godstone, Surrey or on site covering London, Essex, Sussex, Hampshire and Middlesex. At our training centres we provide weekly open-training courses specifically designed to offer value for money for individuals or small groups. We can also offer bespoke courses that can be tailored to meet your specific requirements.

Sales (New and Used Equipment)

Training associated products for sale include:

Body Harnesses – Anemometers – Work Platform – Scaffold Units – Mobile Step Towers

Mobile Aluminium Towers – PASMA Tower Inspection Labels – Ladder Accessories – Mobile Elevated Work Platforms – We will be happy to help and advise you.

Hire an Operator/Erector

We can offer you the opportunity to hire an experienced OTS Operator on a daily or weekly basis on your premises.

Options available are:

Scissor Lifts – Boom Machines – Lorry Mounted – Trailer Mounted Booms – Mobile Access Towers

Operator Training Services is a dedicated training company mainly specialising in Working At Height with the capacity to provide nationally recognised courses throughout the UK with IPAF, PASMA and The Ladder Association.

Our aim is to advance safety standards by instructing our delegates with the necessary knowledge to work safely and to the highest standards. OTS instructors can provide training extensively in the areas below, as they have a wealth of technical knowledge and practical experience. Our instructors, course content and premises are subject to thorough inspection by the Training Scheme Auditors.

IPAF Training Courses – (International Power Access Federation)

MEWP Operator/Demonstrator Training covering scissor lifts, self propelled booms (cherry pickers), vehicle mounted platforms and insulated aerial devices.

PASMA Training Courses – (Prefabricated Access Suppliers’ & Manufacturers’ Association) Mobile Access Tower, Work at Height (Essentials) and Low Level Training.

The Ladder Association – Ladder & Steps User and Inspector Training.

In addition, we can provide our own in-house training for manual handling, abrasive wheels, harnesses and safety awareness.

PASMA, IPAF and The Ladder Association Training can be provided at our training centres based in Ashford, Kent and Godstone, Surrey or on site covering London, Essex, Sussex, Hampshire and Middlesex. At our training centres we provide weekly open-training courses specifically designed to offer value for money for individuals or small groups. We can also offer bespoke courses that can be tailored to meet your specific requirements.

Sales (New and Used Equipment)

Training associated products for sale include:

Body Harnesses – Anemometers – Work Platform – Scaffold Units – Mobile Step Towers

Mobile Aluminium Towers – PASMA Tower Inspection Labels – Ladder Accessories – Mobile Elevated Work Platforms – We will be happy to help and advise you.

Hire an Operator/Erector

We can offer you the opportunity to hire an experienced OTS Operator on a daily or weekly basis on your premises.

Options available are:

Scissor Lifts – Boom Machines – Lorry Mounted – Trailer Mounted Booms – Mobile Access Towers

Reviews & Testimonials for Operator Training Services

February 18, 2020

The tutor and staff were polite, considerate. I would refer this company to others.

Testimonial

by

Alex Ferris

February 18, 2020

All well set out and all in all a good course

Testimonial

by

Samuel Pullen

February 18, 2020

Great Course, great instructors and would recommend

Testimonial

by

Lee Wright

February 18, 2020

Instructors very thorough, inclusive and knowleageble, enjoyed the course throughout

Testimonial

by

Raymond Katsande

December 12, 2019

Enjoyed my days training and felt I had learned alot, especially on Towers as Ive never erected before.

Testimonial

by

Terry Moss

December 12, 2019

Ray was very Helpful

Testimonial

by

Matthew Sharp

December 12, 2019

Come into this blind so this is all new to me, however the course was very interesting and the instructor very knowledgeable.

Testimonial

by

Oliver Heath

December 12, 2019

Useful Course & Associated Conversations

Testimonial

by

Andrew Hewitt

December 11, 2019

Ray is a star

Testimonial

by

Simon Lintott

December 10, 2019

The instructor was very good and helpful, thank you.

Testimonial

by

Haydn Unwin

December 06, 2019

5 Star Service

Testimonial

by

Daniel Morris

December 06, 2019

Nice lunch and instructor was very professional.

Testimonial

by

Jason Botting

November 20, 2019

Informative

Testimonial

by

Robin Voice

November 20, 2019

Very well presented.

Testimonial

by

Justin Robson

November 20, 2019

Could be condensed if less talking and shorter breaks if required.

Testimonial

by

Anna Burse

November 14, 2019

Excellent course, now feel confident to operate equipment.

Testimonial

by

David Burgess

September 04, 2019

Good course as it was done quickly and efficiently and there was no useless info. Training was good and no time was wasted.

Testimonial

by

Jack Bigland

February 27, 2017

From the welcome in the car park through to the end, the course was very good.

Testimonial

by

Tadas Naujokas, Ilford

February 10, 2017

Instructor very supportive and helpful

Testimonial

by

Mervyn Rogers – Guildford

January 10, 2017

Excellent instructor, very good at explaining the entire course.

Testimonial

by

Derek Smith, Eastbourne.

October 26, 2016

Great instructor. Wouldn’t go anywhere else.

Testimonial

by

Tim Deason, Eastbourne

May 30, 2016

A fantastic training centre, recently completed IPAF 1b and 3b course and Ray is a superb instructor. Highly recommended.

Testimonial

by

James Sharp, Sissinghurst,

December 26, 2015

‘Very good Informative Trainer’

Testimonial

by

Ricardo Sesay

July 21, 2015

“very happy with OTS. Ray Whibley was very thorough and answered in all questions – impressed”

Testimonial

by

Vincent Skinner – Ashford

January 15, 2015

Everything very well organised & explained. And lunch provided!

Testimonial

by

Scott Cook

August 10, 2014

Very clear instructions. Went through everything and explained reasons. Friendly instructor. Brilliant overall.

Testimonial

by

Jack Simpkins

April 12, 2013

Hello,

I am writing to thank you for your training courses that I took with yourselves:

Mewps, Harness, Ladder, Abrasive Wheels, and Confined Space.

You may remember me

I paid for those courses myself a few years after I had a Stroke.

Gaining those qualifications gave me an enormous amount of self-confidence, something I was lacking when looking for work.

I truly believe that the certificates I gained from attending and completing these training courses helped me back in to employment.

‘I have to say it was the best investment I have ever taken part in’

I am sorry it took a while to write to you but as you can understand I have been rather

busy with my new job.

Which now brings me on to something I have had in mind for a long time:

Could you please send me details regarding the PASMA Towers for Users and The Scaffold Inspection Course.

I know it will be useful as proven by the other courses.

‘They have paid for themselves many times over’

I am writing to thank you for your training courses that I took with yourselves:

Mewps, Harness, Ladder, Abrasive Wheels, and Confined Space.

You may remember me

I paid for those courses myself a few years after I had a Stroke.

Gaining those qualifications gave me an enormous amount of self-confidence, something I was lacking when looking for work.

I truly believe that the certificates I gained from attending and completing these training courses helped me back in to employment.

‘I have to say it was the best investment I have ever taken part in’

I am sorry it took a while to write to you but as you can understand I have been rather

busy with my new job.

Which now brings me on to something I have had in mind for a long time:

Could you please send me details regarding the PASMA Towers for Users and The Scaffold Inspection Course.

I know it will be useful as proven by the other courses.

‘They have paid for themselves many times over’

Testimonial

by

A Success Story by Alex Ferris

Gallery

|

Click to close

|

Videos

News

25/09/2020

Subscribe to our Newsletter

OTS send out a monthly newsletter with Health and Safety info as well as our training courses. If you would like to receive this newsletter please contact us on 01233 721300 or email us on: training@o-t-s.co.uk

25/09/2020

The QR Code

You will need to scan into our sites using the QR Code that can be downloaded from the app store. This is a Government requirementand we must all comply.

25/09/2020

2021 Calendar

Our 2021 calendar is open to view on our website.

25/09/2020

E-Learning has landed at OTS

If you require IPAF, PASMA or Ladder Training using our E-Learning System, please feel free to contact us on 01233 721300 or training@o-t-s.co.uk

05/03/2020

PASMA Tower Week - 15.03.2020 - 21.03.2020

OTS are having a raffle during March 2020 to promote PASMA Tower Week. If you book a course with us during March, the booker and the delegate/delegates will be entered into a prize draw to win a prize. Good luck to all..

05/03/2020

Working at Height Presentation: Tuesday 24th March 2020

Working at Height Presentation: Tuesday 24th March 2020 An introduction to Woking at Height and the Regulations. Approx: 4hours am or pm session 1. Class Room Session and Practical Demonstrator OTS Certification – certificate of attendance

Please advise if you are interested in attending: 01233 721300 or training@o-t-s.co.uk

Please advise if you are interested in attending: 01233 721300 or training@o-t-s.co.uk

05/03/2020

Training @ Site

If you need Training @ your own site.

For OTS Training at your own site: The following would be required if you require OTS to carry out Training at your own site:

• Training Room – with power points and tables/chairs

• Suitable Area for Practical Session

• Projector Screen

• Ample parking for OTS Trailer and Van

• Equipment for Training purposes or OTS can supply our own

• PPE Operator Training Services Ltd, Hanover Mill, Church Road, Mersham, Ashford, Kent, TN25 6NU 01233 721300 or training@o-t-s.co.uk Travel costs: 0.49per mile from TN25 6NU to postal code of your site (Round Trip) Hire of Equipment – where applicable

For OTS Training at your own site: The following would be required if you require OTS to carry out Training at your own site:

• Training Room – with power points and tables/chairs

• Suitable Area for Practical Session

• Projector Screen

• Ample parking for OTS Trailer and Van

• Equipment for Training purposes or OTS can supply our own

• PPE Operator Training Services Ltd, Hanover Mill, Church Road, Mersham, Ashford, Kent, TN25 6NU 01233 721300 or training@o-t-s.co.uk Travel costs: 0.49per mile from TN25 6NU to postal code of your site (Round Trip) Hire of Equipment – where applicable

05/03/2020

CSCS Card and IPAF PAL Card

IPAF will now be able to have CSCS qualification added to the back of your PAL Card.

IPAF will now be able to have CSCS qualification added to the back of your PAL Card if you can give proof that you have successfully passed this training.

IPAF will now be able to have CSCS qualification added to the back of your PAL Card if you can give proof that you have successfully passed this training.

05/03/2020

PPE

PPE is a requirement for all our Course's.

Please always bring your PPE if you train with us, failure to do so could result in being turned away from the training.

Please always bring your PPE if you train with us, failure to do so could result in being turned away from the training.

05/03/2020

IPAF Fitness Statement

IPAF Health and Fitness Statement

All delegates are required to read this before attending any IPAF Course: PAF HEALTH & FITNESS STATEMENT Since the use of Mobile Elevating Work Platforms (MEWPs) requires that you consult safety notices and read and thoroughly understand the manufacturer’s instruction manual, literacy and language comprehension are important requirements for any MEWP user.

Similarly, since the assembly and use of MEWPs can be physically demanding, users should be physically fit and in good health and should, generally, not have problems with eyesight or hearing, heart disease, high blood pressure, epilepsy, fear of heights / vertigo, giddiness / difficulty with balance, impaired limb function, alcohol or drug dependence or psychiatric illness. If you have any problems with literacy or language comprehension, or have any doubts about your fitness to use a MEWP you must bring them to the attention of your employer.

This need not preclude you from using MEWPs, provided your employer conducts an assessment and is able to put into place adequate measures, to take account of any difficulties you may have.

Operator Training Services Ltd, Hanover Mill, Church Road, Mersham, Ashford, Kent TN25 6NU Tel: 01233 721300

All delegates are required to read this before attending any IPAF Course: PAF HEALTH & FITNESS STATEMENT Since the use of Mobile Elevating Work Platforms (MEWPs) requires that you consult safety notices and read and thoroughly understand the manufacturer’s instruction manual, literacy and language comprehension are important requirements for any MEWP user.

Similarly, since the assembly and use of MEWPs can be physically demanding, users should be physically fit and in good health and should, generally, not have problems with eyesight or hearing, heart disease, high blood pressure, epilepsy, fear of heights / vertigo, giddiness / difficulty with balance, impaired limb function, alcohol or drug dependence or psychiatric illness. If you have any problems with literacy or language comprehension, or have any doubts about your fitness to use a MEWP you must bring them to the attention of your employer.

This need not preclude you from using MEWPs, provided your employer conducts an assessment and is able to put into place adequate measures, to take account of any difficulties you may have.

Operator Training Services Ltd, Hanover Mill, Church Road, Mersham, Ashford, Kent TN25 6NU Tel: 01233 721300

05/03/2020

Fall Protection in MEWPS

Technical Guidance: Mobile Elevating Work Platforms (MEWPS):- Boom Type Platforms: When working from a boom type Mobile Elevating Work Platform (MEWP), it is strongly recommended that a lanyard short enough for the wearer to be restrained within the platform be used.

The lanyard may contain an energy absorbing device, provided it is short enough to restrain the wearer within the platform. This includes Static Booms (1b) and Mobile Booms (3b). Vertical Lifts: It is not normally necessary for personnel working from a vertical lift to wear fall protection equipment, other than in exceptional circumstances.

This includes Static Vertical (1a), Mobile verticals (3a), Push around Verticals (PAV) and Mast Climbing Work Platforms (MCWP). Working next to or over water: A risk assessment should determine whether it is more appropriate to wear a harness to address the fall risk, or a life jacket to address the risk of drowning.

The need for a fall protection system will be the outcome of a job-specific risk assessment undertaken prior to work commencing and taking into consideration the manufacturers operator manual.

05/03/2020

Get Back to Basics

Get back to basics to stay safe: Mobile elevating work platforms (MEWPS) are designed to provide safe access for temporary work at height – but they are only a safe option if the work is planned and managed appropriately.

Accidents can be prevented, through proper planning, risk assessment, and management and supervision of work at height, including operation by trained and familiarisation operators. IPAF’S ‘Back to Basics’ campaign identifies six recognised potential hazards that must be considered if accidents are to be prevented.

These hazards can be avoided if users and operators follow essential safe-use practises. Assess Ground Conditions: Always check ground conditions as part of your site assessment to ensure proper MEWP selection, identify potential hazards, develop control measures, and provide the operator with warning and instructions before using the machine.

Avoid Crushing Hazards: It is essential users and operators identify obstacles that may pose a crushing hazard in any direction of movement with the work platform. Follow the best practice guidance to avoid trapping and crushing injuries in a MEWP available from IPAF’S website www.ipaf.org/safe.

Prevent Unauthorised Use: Consider using a machine capable of reading a Smart PAL Card so that only trained operators can activate machines. After use, always leave the machine in a safe and secure place and remove the key.

Accidents can be prevented, through proper planning, risk assessment, and management and supervision of work at height, including operation by trained and familiarisation operators. IPAF’S ‘Back to Basics’ campaign identifies six recognised potential hazards that must be considered if accidents are to be prevented.

These hazards can be avoided if users and operators follow essential safe-use practises. Assess Ground Conditions: Always check ground conditions as part of your site assessment to ensure proper MEWP selection, identify potential hazards, develop control measures, and provide the operator with warning and instructions before using the machine.

Avoid Crushing Hazards: It is essential users and operators identify obstacles that may pose a crushing hazard in any direction of movement with the work platform. Follow the best practice guidance to avoid trapping and crushing injuries in a MEWP available from IPAF’S website www.ipaf.org/safe.

Prevent Unauthorised Use: Consider using a machine capable of reading a Smart PAL Card so that only trained operators can activate machines. After use, always leave the machine in a safe and secure place and remove the key.

12/12/2019

Falls from Height

Two companies fined after employee Falls from Height

Two firms have been fined after an employee of a construction company fell through a roof onto a concrete floor below.

Lincoln Magistrates’ Court heard how on 23 January 2018 an employee of Italian construction company Zamperoni F.lli srl was refurbishing a shed structure at casting company Bifrangi UK, Lincoln.

As the man worked on the roof he stepped backwards from metal sheeting he was standing on onto a fragile roof light. The plastic material broke under his weight and he fell 5.44 metres to the ground. He sustained two broken arms and three broken ribs.

An investigation by the Health and Safety Executive (HSE) revealed both companies failed to risk assess and plan all aspects of the construction work on site, and failed to ensure the risks from the fragile roof lights were adequately controlled. Both companies also failed to ensure there was adequate safe access onto the roof of the shed. There was inadequate supervision and management checks throughout the work. They also failed to act on the previous instances of unsafe work to ensure safety.

Bifrangi UK of Shardlow Works, Grange Mill Lane, Sheffield pleaded guilty to breaching Section 2(1) and Section 3(1) of the Health and Safety at Work etc Act and was fined £140,000 and ordered to pay costs of £2,607.

Zamperoni F.lli srl of Via Strada Muson, 17-31011 Asolo (TV) Italy was not present in court, but in its absence was fined £54,000 and ordered to pay costs of £1,240.

Speaking after the hearing HSE inspector Martin Giles said:

“Falls from height remain one of the most common causes of work-related fatalities in this country and the risks associated with working at height are well known.

“In this case the use of simple protective measures to prevent falls from and through the fragile roof light would have prevented the injury to this worker. Contractors working in host employers’ premises require adequate supervision and controls to ensure that they are working safely.”

Two firms have been fined after an employee of a construction company fell through a roof onto a concrete floor below.

Lincoln Magistrates’ Court heard how on 23 January 2018 an employee of Italian construction company Zamperoni F.lli srl was refurbishing a shed structure at casting company Bifrangi UK, Lincoln.

As the man worked on the roof he stepped backwards from metal sheeting he was standing on onto a fragile roof light. The plastic material broke under his weight and he fell 5.44 metres to the ground. He sustained two broken arms and three broken ribs.

An investigation by the Health and Safety Executive (HSE) revealed both companies failed to risk assess and plan all aspects of the construction work on site, and failed to ensure the risks from the fragile roof lights were adequately controlled. Both companies also failed to ensure there was adequate safe access onto the roof of the shed. There was inadequate supervision and management checks throughout the work. They also failed to act on the previous instances of unsafe work to ensure safety.

Bifrangi UK of Shardlow Works, Grange Mill Lane, Sheffield pleaded guilty to breaching Section 2(1) and Section 3(1) of the Health and Safety at Work etc Act and was fined £140,000 and ordered to pay costs of £2,607.

Zamperoni F.lli srl of Via Strada Muson, 17-31011 Asolo (TV) Italy was not present in court, but in its absence was fined £54,000 and ordered to pay costs of £1,240.

Speaking after the hearing HSE inspector Martin Giles said:

“Falls from height remain one of the most common causes of work-related fatalities in this country and the risks associated with working at height are well known.

“In this case the use of simple protective measures to prevent falls from and through the fragile roof light would have prevented the injury to this worker. Contractors working in host employers’ premises require adequate supervision and controls to ensure that they are working safely.”

12/12/2019

IPAF MEWPS Training in different Lanquages

IPAF have increased the number of Operator Theory Test Paper Languages to 25.

(IPAF MEWPS Training Course only)

They are now available for you to use in the following languages:

Albanian AL Italian IT

Bulgarian BG

Lithuanian LT Chinese (simplified) CHS North American English NA-EN

Chinese (traditional) CHT Polish PL

Czech CZ Portugese PT

Danish DK Punjabi PA

Dutch NL Romanian RO

English EN Russian RU

Finnish FI Serbian SR

French FR Spanish ES

German DE Swedish SV

Hindi HI Turkish TR

Hungarian HU

(IPAF MEWPS Training Course only)

They are now available for you to use in the following languages:

Albanian AL Italian IT

Bulgarian BG

Lithuanian LT Chinese (simplified) CHS North American English NA-EN

Chinese (traditional) CHT Polish PL

Czech CZ Portugese PT

Danish DK Punjabi PA

Dutch NL Romanian RO

English EN Russian RU

Finnish FI Serbian SR

French FR Spanish ES

German DE Swedish SV

Hindi HI Turkish TR

Hungarian HU

12/12/2019

Working at Height Regulations

Working at Height Regulations:

Introduction:

This brief guide describes what you, as an employer, need to do to protect your employees from falls from height. It will also be useful to employees and their representatives. Following this guidance is normally enough to comply with the Work at Height Regulations 2005 (WAHR). You are free to take other action, except where the guidance says you must do something specific. Falls from height are one of the biggest causes of workplace fatalities and major injuries. Common causes are falls from ladders and through fragile roofs. The purpose of WAHR is to prevent death and injury from a fall from height. Work at height means work in any place where, if there were no precautions in place, a person could fall a distance liable to cause personal injury.

For example you are working at height if you:

are working on a ladder or a flat roof;

could fall through a fragile surface;

could fall into an opening in a floor or a hole in the ground.

Take a sensible approach when considering precautions for work at height. There may be some low-risk situations where common sense tells you no particular precautions are necessary and the law recognises this. There is a common misconception that ladders and stepladders are banned, but this is not the case. There are many situations where a ladder is the most suitable equipment for working at height. Before working at height you must work through these simple steps:

avoid work at height where it is reasonably practicable to do so;

where work at height cannot be avoided, prevent falls using either an existing place of work that is already safe or the right type of equipment;

minimise the distance and consequences of a fall, by using the right type of equipment where the risk cannot be eliminated.

You should:

do as much work as possible from the ground;

ensure workers can get safely to and from where they work at height;

ensure equipment is suitable, stable and strong enough for the job, maintained and checked regularly;

Working at height A brief guide

This is a web-friendly version of leaflet INDG401(rev2), published 01/14

Health and Safety

Executive

Working at height Page 2 of 7

make sure you don’t overload or overreach when working at height;

take precautions when working on or near fragile surfaces;

provide protection from falling objects;

consider your emergency evacuation and rescue procedures.

Who do the Regulations apply to?

If you are an employer or you control work at height (for example if you are a contractor or a factory owner), the Regulations apply to you.

How do you comply with these Regulations?

Employers and those in control of any work at height activity must make sure work is properly planned, supervised and carried out by competent people. This includes using the right type of equipment for working at height. Low-risk, relatively straightforward tasks will require less effort when it comes to planning. Employers and those in control must first assess the risks. See the risk assessment website for more advice at www.hse.gov.uk/risk/risk-assessment.htm. Take a sensible, pragmatic approach when considering precautions for work at height. Factors to weigh up include the height of the task; the duration and frequency; and the condition of the surface being worked on. There will also be certain low-risk situations where common sense tells you no particular precautions are necessary.

How do you decide if someone is ‘competent’ to work at height?

You should make sure that people with sufficient skills, knowledge and experience are employed to perform the task, or, if they are being trained, that they work under the supervision of somebody competent to do it.

In the case of low-risk, short duration tasks (short duration means tasks that take less than 30 minutes) involving ladders, competence requirements may be no more than making sure employees receive instruction on how to use the equipment safely (eg how to tie a ladder properly) and appropriate training. Training often takes place on the job, it does not always take place in a classroom.

When a more technical level of competence is required, for example drawing up a plan for assembling a complex scaffold, existing training and certification schemes drawn up by trade associations and industry is one way to help demonstrate competence.

What measures should you take to help protect people?

Always consider measures that protect everyone who is at risk (collective protection) before measures that protect only the individual (personal protection).

Collective protection is equipment that does not require the person working at height to act to be effective, for example a permanent or temporary guard rail.

Personal protection is equipment that requires the individual to act to be effective. An example is putting on a safety harness correctly and connecting it, via an energy-absorbing lanyard, to a su

Introduction:

This brief guide describes what you, as an employer, need to do to protect your employees from falls from height. It will also be useful to employees and their representatives. Following this guidance is normally enough to comply with the Work at Height Regulations 2005 (WAHR). You are free to take other action, except where the guidance says you must do something specific. Falls from height are one of the biggest causes of workplace fatalities and major injuries. Common causes are falls from ladders and through fragile roofs. The purpose of WAHR is to prevent death and injury from a fall from height. Work at height means work in any place where, if there were no precautions in place, a person could fall a distance liable to cause personal injury.

For example you are working at height if you:

are working on a ladder or a flat roof;

could fall through a fragile surface;

could fall into an opening in a floor or a hole in the ground.

Take a sensible approach when considering precautions for work at height. There may be some low-risk situations where common sense tells you no particular precautions are necessary and the law recognises this. There is a common misconception that ladders and stepladders are banned, but this is not the case. There are many situations where a ladder is the most suitable equipment for working at height. Before working at height you must work through these simple steps:

avoid work at height where it is reasonably practicable to do so;

where work at height cannot be avoided, prevent falls using either an existing place of work that is already safe or the right type of equipment;

minimise the distance and consequences of a fall, by using the right type of equipment where the risk cannot be eliminated.

You should:

do as much work as possible from the ground;

ensure workers can get safely to and from where they work at height;

ensure equipment is suitable, stable and strong enough for the job, maintained and checked regularly;

Working at height A brief guide

This is a web-friendly version of leaflet INDG401(rev2), published 01/14

Health and Safety

Executive

Working at height Page 2 of 7

make sure you don’t overload or overreach when working at height;

take precautions when working on or near fragile surfaces;

provide protection from falling objects;

consider your emergency evacuation and rescue procedures.

Who do the Regulations apply to?

If you are an employer or you control work at height (for example if you are a contractor or a factory owner), the Regulations apply to you.

How do you comply with these Regulations?

Employers and those in control of any work at height activity must make sure work is properly planned, supervised and carried out by competent people. This includes using the right type of equipment for working at height. Low-risk, relatively straightforward tasks will require less effort when it comes to planning. Employers and those in control must first assess the risks. See the risk assessment website for more advice at www.hse.gov.uk/risk/risk-assessment.htm. Take a sensible, pragmatic approach when considering precautions for work at height. Factors to weigh up include the height of the task; the duration and frequency; and the condition of the surface being worked on. There will also be certain low-risk situations where common sense tells you no particular precautions are necessary.

How do you decide if someone is ‘competent’ to work at height?

You should make sure that people with sufficient skills, knowledge and experience are employed to perform the task, or, if they are being trained, that they work under the supervision of somebody competent to do it.

In the case of low-risk, short duration tasks (short duration means tasks that take less than 30 minutes) involving ladders, competence requirements may be no more than making sure employees receive instruction on how to use the equipment safely (eg how to tie a ladder properly) and appropriate training. Training often takes place on the job, it does not always take place in a classroom.

When a more technical level of competence is required, for example drawing up a plan for assembling a complex scaffold, existing training and certification schemes drawn up by trade associations and industry is one way to help demonstrate competence.

What measures should you take to help protect people?

Always consider measures that protect everyone who is at risk (collective protection) before measures that protect only the individual (personal protection).

Collective protection is equipment that does not require the person working at height to act to be effective, for example a permanent or temporary guard rail.

Personal protection is equipment that requires the individual to act to be effective. An example is putting on a safety harness correctly and connecting it, via an energy-absorbing lanyard, to a su

12/12/2019

RAMS

Risk Assessments & Method Statements:

Introduction:

This Toolbox -talk will cover what Risk Assessments and Method Statements mean to you.

Main Points:

Risk Assessments:

Under Regulation 3 of the Management of Health and Safety at Work Regulations 1999, every employer and self-employed person has a legal duty to conduct Risk Assessments for their work activities that could result in injury to people or damage to equipment.

Those that employ 5 or more employess should record the significant findings of the Risk Assessment.

Method Statements:

Method Statements are a written Safe System of Work, to be carried out in a specific sequence, in order to complete the operation in a safe and efficient manner.

Risk Assessments and Method Statements are often referred to as RAMS.

Discussion Points:

Risk Assessments:

All employers have a legal duty to prepare Risk Assessments for work activities that could result injury to people or damage to equipment.

Risk Assessments outline the ways in which injury could occur and put in place control measures to eliminate or reduce the level of risk to an acceptable level.

Employers with 5 or more employees must have written Risk Assessments. With less than 5 employees, you must still carry out a Risk Assessment but do not have to write it down.

Employers have a legal duty to communicate the findings of the Risk Assessment to operatives who may be affected.

Method Statements:

Method Statements are a written Safe System of Work, to be carried out in a specific sequence, in order to complete the operation in a safe and efficient manner.

Everyone involved in a job for which a Method Statement has been written should read and sign to say that they have done so.

Method Statements look at the hazards present and plan the work so that the risk of an accident is eliminated or reduced to an acceptable level.

Most Method Statements include a copy of the Risk Assessment for the same job so that the operatives can read what hazards have been considered and how the risks of the accident have been overcome.

Introduction:

This Toolbox -talk will cover what Risk Assessments and Method Statements mean to you.

Main Points:

Risk Assessments:

Under Regulation 3 of the Management of Health and Safety at Work Regulations 1999, every employer and self-employed person has a legal duty to conduct Risk Assessments for their work activities that could result in injury to people or damage to equipment.

Those that employ 5 or more employess should record the significant findings of the Risk Assessment.

Method Statements:

Method Statements are a written Safe System of Work, to be carried out in a specific sequence, in order to complete the operation in a safe and efficient manner.

Risk Assessments and Method Statements are often referred to as RAMS.

Discussion Points:

Risk Assessments:

All employers have a legal duty to prepare Risk Assessments for work activities that could result injury to people or damage to equipment.

Risk Assessments outline the ways in which injury could occur and put in place control measures to eliminate or reduce the level of risk to an acceptable level.

Employers with 5 or more employees must have written Risk Assessments. With less than 5 employees, you must still carry out a Risk Assessment but do not have to write it down.

Employers have a legal duty to communicate the findings of the Risk Assessment to operatives who may be affected.

Method Statements:

Method Statements are a written Safe System of Work, to be carried out in a specific sequence, in order to complete the operation in a safe and efficient manner.

Everyone involved in a job for which a Method Statement has been written should read and sign to say that they have done so.

Method Statements look at the hazards present and plan the work so that the risk of an accident is eliminated or reduced to an acceptable level.

Most Method Statements include a copy of the Risk Assessment for the same job so that the operatives can read what hazards have been considered and how the risks of the accident have been overcome.

12/04/2013

A Success Story by Alex Ferris

Hello,

I am writing to thank you for your training courses that I took with yourselves:

Mewps, Harness, Ladder, Abrasive Wheels, and Confined Space.

You may remember me

I paid for those courses myself a few years after I had a Stroke.

Gaining those qualifications gave me an enormous amount of self-confidence, something I was lacking when looking for work.

I truly believe that the certificates I gained from attending and completing these training courses helped me back in to employment.

‘I have to say it was the best investment I have ever taken part in’

I am sorry it took a while to write to you but as you can understand I have been rather

busy with my new job.

Which now brings me on to something I have had in mind for a long time:

Could you please send me details regarding the PASMA Towers for Users and The Scaffold Inspection Course.

I know it will be useful as proven by the other courses.

‘They have paid for themselves many times over’

I am writing to thank you for your training courses that I took with yourselves:

Mewps, Harness, Ladder, Abrasive Wheels, and Confined Space.

You may remember me

I paid for those courses myself a few years after I had a Stroke.

Gaining those qualifications gave me an enormous amount of self-confidence, something I was lacking when looking for work.

I truly believe that the certificates I gained from attending and completing these training courses helped me back in to employment.

‘I have to say it was the best investment I have ever taken part in’

I am sorry it took a while to write to you but as you can understand I have been rather

busy with my new job.

Which now brings me on to something I have had in mind for a long time:

Could you please send me details regarding the PASMA Towers for Users and The Scaffold Inspection Course.

I know it will be useful as proven by the other courses.

‘They have paid for themselves many times over’

Products & Services

Abrasive Wheels Training

Harness Training

Confined Space Training

Ladder Training Courses

PASMA Training

IPAF Training

MEWPs Training

Team

| Name | Role | Telephone | |

| Sally Farmer | Marketing Administrator | training@o-t-s.co.uk | 01233 721300 |

| Helen Whibley | Director | training@o-t-s.co.uk | 01233 721300 |

| Kaz Rowell | Senior Administrator | training@o-t-s.co.uk | 01233 721300 |

| Ray Whibley | Senior Director | training@o-t-s.co.uk | 01233 721300 |

Location Map

Operator Training Services Serves The Following Areas

Find Operator Training Services in

Operator Training Services Branches

Operator Training Services

Hanover Mill, Church Road, Mersham, Ashford, TN25 6NU

Hanover Mill, Church Road, Mersham, Ashford, TN25 6NU

Click to view telephone number