Time and date

CONSTRUCTION DIRECTORY

Therma-Crete Contact Details

Address

Robert S Maynard Ltd. P O Box 8, Beech Lane House, Wilmslow, Cheshire, SK9 5ES England

Wilmslow

SK9 5ES

England UK

About Therma-Crete

Therma-Crete Concrete Frost Curing Blankets are a revolutionary new system providing protection to early age concrete, preventing damage from freezing and ensuring development of adequate strength.

The use of the blankets enables concreting laying to be undertaken in cold ambient conditions, allowing strength development and durability to satisfy service requirements.

Cold weather is generally regarded as being when the average daily ambient air temperature is less than 5°C or when the air temperature is not greater than 10°C for more than one half of any 24hr period.

Concreting during periods as defined above result in the following complications:

Lightweight and easy to handle, the Therma-Crete® blankets help fresh concrete to cure in cold weather. Fresh concrete has its own heat, called heat of hydration. In many circumstances, if properly trapped and insulated, this heat will be generated in sufficient quantity to be the only source of heat necessary during a 3 day curing cycle whilst insulating it from the environment. and ambient air temperature.

Pre-cast Concrete

Therma-Crete can be used to accelerate the manufacture of concrete elements in precast units, replacing existing, antiquated curing practices.

By using Therma-Crete Curing Blankets, the concrete cures far more rapidly which reduces lead times in manufacturing, cutting energy costs and improving health & safety.

Advantages

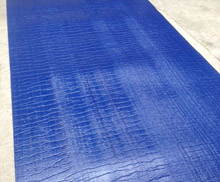

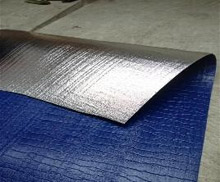

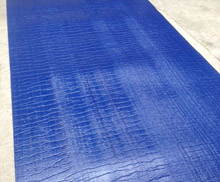

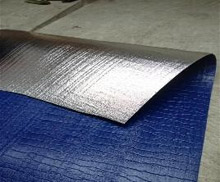

Our concrete curing blankets are designed for both hot and cold weather, adding reflective technology to the curing process. This allows the concrete to maintain sufficient levels of water and heat so that the concrete can achieve its desired physical properties. Constructed from laminated layers of tough woven polypropylene, aluminum, and foam insulation material.

The use of the blankets enables concreting laying to be undertaken in cold ambient conditions, allowing strength development and durability to satisfy service requirements.

Cold weather is generally regarded as being when the average daily ambient air temperature is less than 5°C or when the air temperature is not greater than 10°C for more than one half of any 24hr period.

Concreting during periods as defined above result in the following complications:

- The degree of saturation of the concrete falls below critical level.

- The concrete freezes before a minimum strength of 3.5MPa has been achieved.

- The hydration reaction of the concrete stops and the concrete does not gain strength.

Lightweight and easy to handle, the Therma-Crete® blankets help fresh concrete to cure in cold weather. Fresh concrete has its own heat, called heat of hydration. In many circumstances, if properly trapped and insulated, this heat will be generated in sufficient quantity to be the only source of heat necessary during a 3 day curing cycle whilst insulating it from the environment. and ambient air temperature.

Pre-cast Concrete

Therma-Crete can be used to accelerate the manufacture of concrete elements in precast units, replacing existing, antiquated curing practices.

By using Therma-Crete Curing Blankets, the concrete cures far more rapidly which reduces lead times in manufacturing, cutting energy costs and improving health & safety.

Advantages

Our concrete curing blankets are designed for both hot and cold weather, adding reflective technology to the curing process. This allows the concrete to maintain sufficient levels of water and heat so that the concrete can achieve its desired physical properties. Constructed from laminated layers of tough woven polypropylene, aluminum, and foam insulation material.

- Allows concreting operations in low ambient temperature conditions.

- Allows earlier release of pre-stress.

- Reduced time to impose loading.

- Allows more precise project scheduling, as concrete pours are more likely to take place.

- Reduced project stoppages and overall completion time.

- Simple storage; re-usable.

- Elimination of temporary enclosures.

- Improved health & safety on site, through elimination of naked flame burners.

- No risk of carbonation to concrete - a consequence of using open flame burners.

Order online or call +44(0)1625 251000