Time and date

CONSTRUCTION DIRECTORY

Isopod Rapid Cleanrooms Contact Details

Address

Unit 2 & 3

Highbury Road

Highbury Road

Brandon

IP27 0ND

England UK

Opening Hours

Tuesday

08:30-17:00

Monday

08:30-17:00

Tuesday

08:30-17:00

Wednesday

08:30-17:00

Thursday

08:30-17:00

Friday

08:30-17:00

Saturday

Closed

Sunday

Closed

Other Dates

About Isopod Rapid Cleanrooms

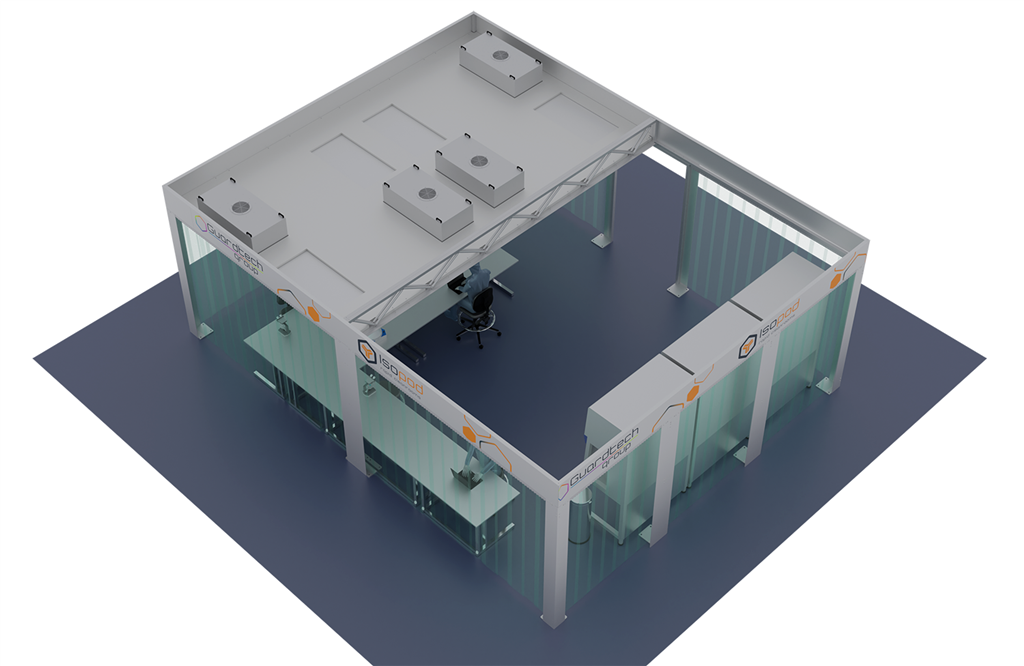

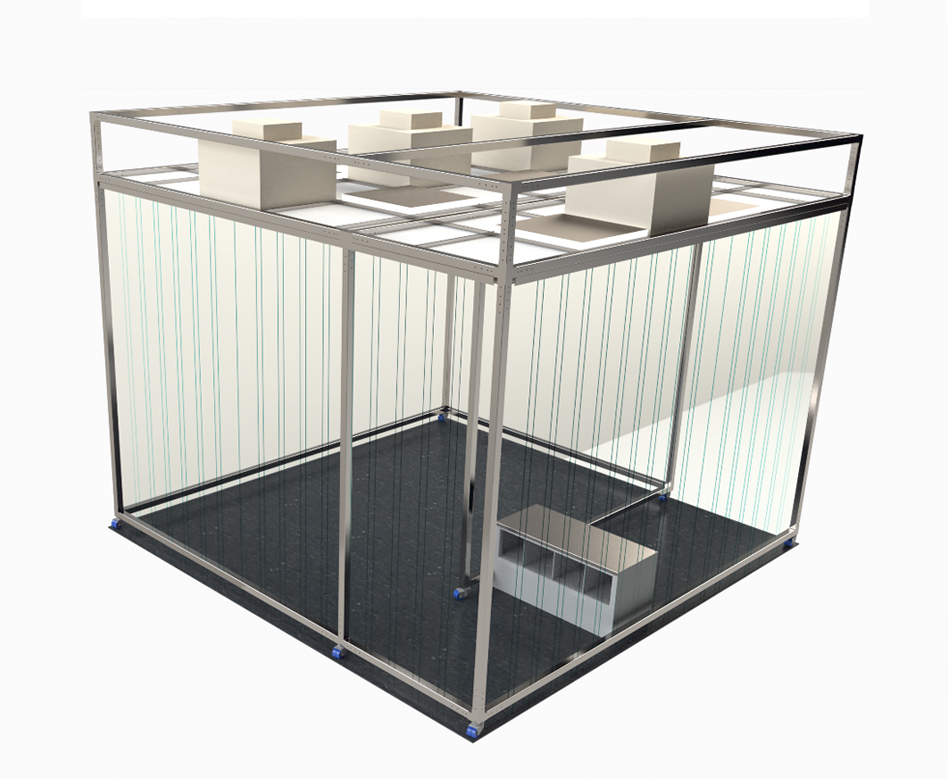

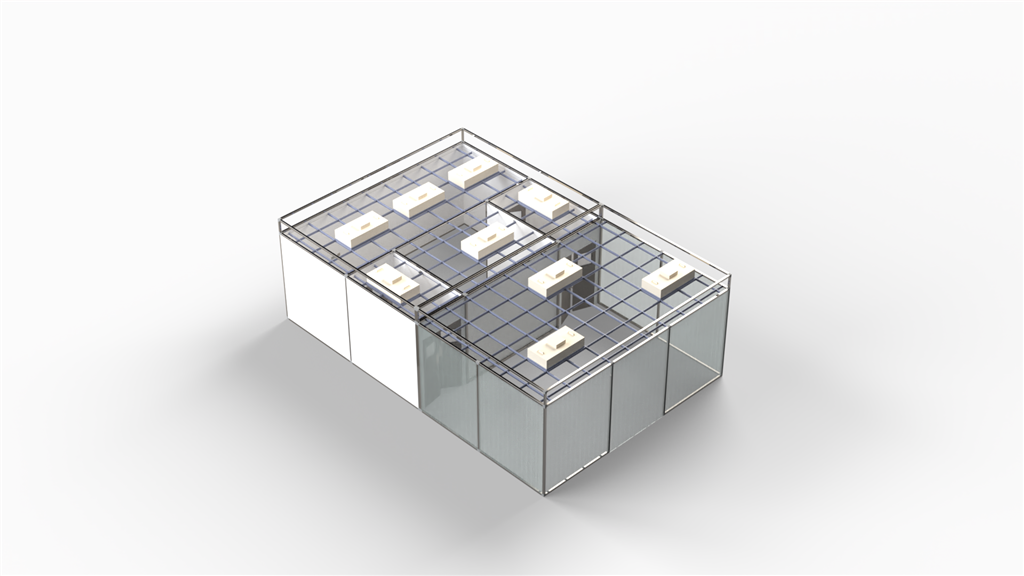

Isopod is a revolutionary concept in modular cleanroom design & build. Isopods are high-performance controlled environments which can be rapidly self-assembled and are fully customisable to best utilise the host room they are installed within.

Combining high-quality construction materials with state-of-the-art cleanroom technology, Isopods are the perfect solution to upgrading Production environments, R&D applications, Education or Healthcare facilities in a sustainable, practical and cost-effective way.

Isopods can be reconfigured, relocated, extended and upgraded – growing alongside your business, evolving with your needs. Shipped worldwide ready for quick and simple self-assembly, supported by full installation instructions and demo movies.

Alternatively these can be delivered & installed quickly by Guardtech’s experienced Isopod engineers.

- Ships worldwide for self-assembly

- Can be reconfigured, relocated and extended

- Available as hardwall, softwall or hybrid cleanroom

- Changing room/materials interlock modules

- Can be static or mobile on casters

- Can be upgraded or modified as your business grows

- Energy efficient – only control the area that requires it

- Can be branded in corporate colours, logo, graphics

- Removable panels for equipment transfer

- Glazing can be added to hardwall

Combining high-quality construction materials with state-of-the-art cleanroom technology, Isopods are the perfect solution to upgrading Production environments, R&D applications, Education or Healthcare facilities in a sustainable, practical and cost-effective way.

Isopods can be reconfigured, relocated, extended and upgraded – growing alongside your business, evolving with your needs. Shipped worldwide ready for quick and simple self-assembly, supported by full installation instructions and demo movies.

Alternatively these can be delivered & installed quickly by Guardtech’s experienced Isopod engineers.

- Ships worldwide for self-assembly

- Can be reconfigured, relocated and extended

- Available as hardwall, softwall or hybrid cleanroom

- Changing room/materials interlock modules

- Can be static or mobile on casters

- Can be upgraded or modified as your business grows

- Energy efficient – only control the area that requires it

- Can be branded in corporate colours, logo, graphics

- Removable panels for equipment transfer

- Glazing can be added to hardwall

Reviews & Testimonials for Isopod Rapid Cleanrooms

August 01, 2024

Gary Poole, Project Manager at ChargePoint Technology, said: “Guardtech have a professional and friendly team, always discussed through the daily/weekly works with the client and addressed any issues snags captured during the build process, rather than waiting until the end of the project. Good housekeeping upheld throughout the build."

Testimonial

by

ChargePoint Technology

April 01, 2024

Gabor Geczy, Project Manager for BHE Bonn Hungary Electronics Ltd, said: “I would like to thank the Guardtech team for the quick work and the flexibility during this Isopod cleanroom procurement, we appreciate that.

“The install team did a great job – we tried to help them in any way we could and they appreciated that, too. A great co-operation here in Budapest resulted in an Isopod Rapid Cleanroom which is now working great.”

“The install team did a great job – we tried to help them in any way we could and they appreciated that, too. A great co-operation here in Budapest resulted in an Isopod Rapid Cleanroom which is now working great.”

Testimonial

by

BHE Bonn Hungary Electronics Ltd

March 01, 2024

A leading Surrey-based Defence contractor said: "The cleanroom was good value for money when contrasted with offerings from other suppliers – and the final quality of the cleanroom was very good.

“There was excellent communication from the Project Manager of the cleanroom delivery throughout the build. Any problems were dealt with very well and professionally handled, with a lot of flexibility shown whenever possible. Particular thanks to Arran Williams for this at-times challenging build.

“Guardtech were very accommodating of unusual designs and requests, there was nothing too big or too small that they couldn’t deliver. That level of flexibility cannot be said for most other suppliers.”

“There was excellent communication from the Project Manager of the cleanroom delivery throughout the build. Any problems were dealt with very well and professionally handled, with a lot of flexibility shown whenever possible. Particular thanks to Arran Williams for this at-times challenging build.

“Guardtech were very accommodating of unusual designs and requests, there was nothing too big or too small that they couldn’t deliver. That level of flexibility cannot be said for most other suppliers.”

Testimonial

by

A leading Surrey-based Defence contractor

December 01, 2023

Tony Cooke, CEO at Cambridge Clinical Laboratories, said: “The CleanCube is up and running and we’ve been approved by the government Health & Safety Executive to use it. We’re developing a novel tuberculosis test and now have our first samples in place. This is an entirely new process from what we’ve done previously in the lab and part of it needs to be conducted in a Category 3 containment suite.

“The solution was a lot more convenient than any other option in the market. We had really tight timescales and we’re in a rented building – so we’d have had to get landlord’s permission, go through all the planning consent, so this is just so much quicker.

“The CleanCube team were brilliant to work – Michael Burton, in particular, was fantastic. I’d highly recommend the Guardtech Group as a containment lab provider.”

“The solution was a lot more convenient than any other option in the market. We had really tight timescales and we’re in a rented building – so we’d have had to get landlord’s permission, go through all the planning consent, so this is just so much quicker.

“The CleanCube team were brilliant to work – Michael Burton, in particular, was fantastic. I’d highly recommend the Guardtech Group as a containment lab provider.”

Testimonial

by

Cambridge Clinical Laboratories

July 01, 2023

John Bowden, Atec Managing Director, said: "Guardtech installed an Isopod Shell Hardwall rapid cleanroom for us. The process felt simple and installation was quick. We had a few minor delays, but they were communicated and were not a problem to us. Overall, were very satisfied with the build quality and customer service."

Testimonial

by

Atec Engineering Solutions

July 01, 2023

Chris McGuinness, Strategic Projects Director at Biocomposites Ltd., said: “Guardtech has proved to be a supplier of the highest standard throughout the whole process of providing a new manufacturing facility to support the growth of our product range. Excellent project management was demonstrated in design, build and commissioning phases.

“Site safety was managed effectively and disruption to neighbouring tenants was kept to a minimum. The extensive knowledge and experience of the teams involved aided our decision making to ensure all requirements were met. The success of this project has given us the confidence to contract Guardtech’s turnkey arm Cleanroom Solutions to provide further manufacturing capacity and construction of another suite is now underway.”

“Site safety was managed effectively and disruption to neighbouring tenants was kept to a minimum. The extensive knowledge and experience of the teams involved aided our decision making to ensure all requirements were met. The success of this project has given us the confidence to contract Guardtech’s turnkey arm Cleanroom Solutions to provide further manufacturing capacity and construction of another suite is now underway.”

Testimonial

by

Biocomposites

June 01, 2023

Sean Licence, Head of Medical at JEB Technologies Ltd, said: “The cleanroom that Guardtech have built for us has exceeded our expectations for quality and time to delivery. From the first engagement with the sales team, right through to the team building and installing the cleanroom, Guardtech as a company have been thoroughly professional and really easy to work with. We will definitely be using them again in the future, and I would highly recommend Guardtech to others looking to have cleanrooms installed.”

Testimonial

by

JEB Technologies Ltd

June 01, 2023

NSP Expert Lab Solutions Managing Director Graham Devitt said: “It has been a pleasure to collaborate with Guardtech again to deliver a 60sqm modular build in Dublin. Their knowledge, experience, quality and attention to detail have yet again ensured that this project was delivered in a successful, timely and professional manner. Mark, Conor, Andrew and the Guardtech team are experts in their area and always a pleasure to work with and we look forward to collaborating on many more projects together in the future.”

Testimonial

by

NSP Expert Lab Solutions

June 01, 2023

Dean Powell, Group MEP Director at COEL, said: “COEL were employed by Sense Biodetection to deliver their new Cambridge facility which would enable their requirement for enhanced capabilities. Having worked with Guardtech previously we felt they were the obvious choice to deliver the specialist cleanrooms.

“From the outset Guardtech proved to be invaluable, offering both their experience, technical knowledge and showed a real willingness to engage with the project design team. Throughout the design phase the team worked with the client to design a facility that not only met their design brief but also functioned efficiently and took into consideration flexibility for future expansion.

“I was impressed with Guardtech’s delivery of the cleanrooms – the programme was tight and despite changes in the client’s requirements, they managed to incorporate these changes and still deliver the project on time and to an exceptional standard. I look forward to working with Guardtech on future projects.”

“From the outset Guardtech proved to be invaluable, offering both their experience, technical knowledge and showed a real willingness to engage with the project design team. Throughout the design phase the team worked with the client to design a facility that not only met their design brief but also functioned efficiently and took into consideration flexibility for future expansion.

“I was impressed with Guardtech’s delivery of the cleanrooms – the programme was tight and despite changes in the client’s requirements, they managed to incorporate these changes and still deliver the project on time and to an exceptional standard. I look forward to working with Guardtech on future projects.”

Testimonial

by

COEL/Sense Biodetection

September 01, 2022

Edward Cockroft, Laboratory Implementation Manager at Cignpost Diagnostics, said: "Guardtech have been a trusted partner and supplier for us here at Cignpost Diagnostics. They've enabled us to deliver fast and accurate COVID-19 testing solutions to our elite Sports, Film, and Airport clients.

“Their world-class range of mobile testing units, from their CleanCube Vans to their 40ft CleanCube BS2 laboratories, have enabled us to provide our clients with flexible and dynamic onsite testing facilities that can used anywhere in the world. It had been a pleasure working with Guardtech over the past two years and we look forward to seeing what we can achieve together in the future."

“Their world-class range of mobile testing units, from their CleanCube Vans to their 40ft CleanCube BS2 laboratories, have enabled us to provide our clients with flexible and dynamic onsite testing facilities that can used anywhere in the world. It had been a pleasure working with Guardtech over the past two years and we look forward to seeing what we can achieve together in the future."

Testimonial

by

Cignpost Diagnostics

Gallery

|

Click to close

|

Videos

News

29/08/2024

New era for Isopod Rapid Cleanrooms

THE GUARDTECH GROUP are ushering in a new era of quick-assembly cleanroom excellence with a series of exciting developments regarding their Isopod Rapid Cleanrooms brand.

The Haverhill-based controlled environment construction specialists recently launched an exciting new website for Isopod – www.iso-pod.co.uk – an innovative site that takes clients through the most comprehensive, small-scale cleanroom procurement process on the market.

Guardtech’s new site hosts their revolutionary ‘build your own cleanroom’ Isopod Configurator alongside in-depth Isopod model pages, helpful Technical component content and illuminating case studies.

What’s more, there are also now all-new Configurations pages for the Shell (Hardwall), Flexi (Softwall) and Hybrid (Genus) models, which outline the standard 2x3m, 3x3m, 3x4m, 4x4m and 5x3m pod options, as well as standard PAL/MAL dual airlock Configurations for each size.

Guardtech have invested significantly in R&D over the 12 months to develop what they believe are their most compelling Shell, Flexi and Hybrid model prototypes yet.

The latest Isopods promise to be the most robust, reliable, high-performance modules in the brand’s history – a process led by Isopod/CleanCube Manufacturing Manager Michael Burton and Guardtech Group ISO Commercial Manager Andrew Cressey.

“Isopod, as a high-quality, quick-assembly cleanroom product, is now better than ever before,” says Cressey. “The idea with this newly streamlined and standardised process is to make buying a rapid, small-scale cleanroom pod as straightforward as possible.”

Cressey has been delivering smaller scale cleanroom pods, alongside more large-scale, complex facilities, for more than a decade.

He’s utilised his wealth of experience to help the Group develop the most efficient, customer-friendly service in the history of Isopod.

“I’ve been providing cleanroom systems like Isopod for a long time now, so I know better than most what clients need – and how they want the process to unfold in terms of procuring these units.

“Ultimately, many customers will still require a bespoke system, but the idea with these new standard Configurations is that a potential new client can quickly and easily see what options they’ve got, in terms of basic process room plus Personnel and Materials Airlocks layouts, and then make a super-quick, informed decision as to how they want to move forward.”

Guardtech’s Isopod Rapid Cleanrooms Brochure has also been given an update as part of the brand refresh, with more in-depth focus on the three base models, Configurations content and much more.

And the brand now has a newly established two-pronged, dedicated sales team in the form of Jack Pummell and Steve Bawa.

The Guardtech Group Business Development Managers will offer a more concentrated client-centred service in the North (Bawa) and South (Pummell), taking the brand’s streamlined approach to a whole new level.

Bawa, who joined Guardtech three months ago and, like Pummell, also provides Cleanroom Service Plans, facility Decontamination Agreements and cleanroom-grade furniture & equipment, is thrilled to have joined Guardtech at such an exciting time.

“I’m delighted to be involved with Isopod – it’s such an amazing, innovative product,” he says. “Guardtech have a long history of excellence in terms of cleanroom construction – and you can see all the hallmarks of their expertise in the quality of the modules.

“Establishing that level of trusted intellectual property has obviously come over years and years of building complex cleanrooms – and you can really see that in Isopod.

“I’m looking forward to providing these brilliant units for clients across the realm of Life Sciences, High-Tech Engineering and Manufacturing.”

For more information on Isopod Rapid Cleanrooms, call 0330 113 0303, email sales@guardtech.com or visit www.iso-pod.co.uk.

The Haverhill-based controlled environment construction specialists recently launched an exciting new website for Isopod – www.iso-pod.co.uk – an innovative site that takes clients through the most comprehensive, small-scale cleanroom procurement process on the market.

Guardtech’s new site hosts their revolutionary ‘build your own cleanroom’ Isopod Configurator alongside in-depth Isopod model pages, helpful Technical component content and illuminating case studies.

What’s more, there are also now all-new Configurations pages for the Shell (Hardwall), Flexi (Softwall) and Hybrid (Genus) models, which outline the standard 2x3m, 3x3m, 3x4m, 4x4m and 5x3m pod options, as well as standard PAL/MAL dual airlock Configurations for each size.

Guardtech have invested significantly in R&D over the 12 months to develop what they believe are their most compelling Shell, Flexi and Hybrid model prototypes yet.

The latest Isopods promise to be the most robust, reliable, high-performance modules in the brand’s history – a process led by Isopod/CleanCube Manufacturing Manager Michael Burton and Guardtech Group ISO Commercial Manager Andrew Cressey.

“Isopod, as a high-quality, quick-assembly cleanroom product, is now better than ever before,” says Cressey. “The idea with this newly streamlined and standardised process is to make buying a rapid, small-scale cleanroom pod as straightforward as possible.”

Cressey has been delivering smaller scale cleanroom pods, alongside more large-scale, complex facilities, for more than a decade.

He’s utilised his wealth of experience to help the Group develop the most efficient, customer-friendly service in the history of Isopod.

“I’ve been providing cleanroom systems like Isopod for a long time now, so I know better than most what clients need – and how they want the process to unfold in terms of procuring these units.

“Ultimately, many customers will still require a bespoke system, but the idea with these new standard Configurations is that a potential new client can quickly and easily see what options they’ve got, in terms of basic process room plus Personnel and Materials Airlocks layouts, and then make a super-quick, informed decision as to how they want to move forward.”

Guardtech’s Isopod Rapid Cleanrooms Brochure has also been given an update as part of the brand refresh, with more in-depth focus on the three base models, Configurations content and much more.

And the brand now has a newly established two-pronged, dedicated sales team in the form of Jack Pummell and Steve Bawa.

The Guardtech Group Business Development Managers will offer a more concentrated client-centred service in the North (Bawa) and South (Pummell), taking the brand’s streamlined approach to a whole new level.

Bawa, who joined Guardtech three months ago and, like Pummell, also provides Cleanroom Service Plans, facility Decontamination Agreements and cleanroom-grade furniture & equipment, is thrilled to have joined Guardtech at such an exciting time.

“I’m delighted to be involved with Isopod – it’s such an amazing, innovative product,” he says. “Guardtech have a long history of excellence in terms of cleanroom construction – and you can see all the hallmarks of their expertise in the quality of the modules.

“Establishing that level of trusted intellectual property has obviously come over years and years of building complex cleanrooms – and you can really see that in Isopod.

“I’m looking forward to providing these brilliant units for clients across the realm of Life Sciences, High-Tech Engineering and Manufacturing.”

For more information on Isopod Rapid Cleanrooms, call 0330 113 0303, email sales@guardtech.com or visit www.iso-pod.co.uk.

06/07/2023

Summer Update: Guardtech blaze a trail at home and abroad over the past six months

SUMMER has arrived and the sun continues to shine on the Guardtech Group – who are enjoying a hot streak both at home and on foreign shores.

Turnkey construction arm Cleanroom Solutions and modular specialists Guardtech Cleanrooms are currently working on seven significant projects between them, including large builds in Germany and Switzerland.

The Group completed a 60sqm ISO6 & 7 Electronics Testing modular in Ireland in May and shipped a 20sqm ISO8 Automotive Isopod Rapid Cleanroom to a client in Morocco last month, having already provided a customer with 30sqm & 45sqm ISO7 Electronics Isopods in Denmark in the spring.

This is all alongside a 60sqm ISO7 Research & Development CleanCube Maxi that was constructed at Guardtech’s UK manufacturing facility and then delivered to Sweden, ready for immediate deployment.

The Group unveiled brand-new websites for portable solution CleanCube (www.cleancube.co.uk) and Cleanroom Solutions (www.cleanroom-solutions.co.uk) earlier this year and are delighted to reveal a new subsite for Guardtech Cleanrooms has just been launched at www.guardtechcleanrooms.com.

It all adds up to another highly fruitful – and busy – six months for the Haverhill-based cleanroom kings and queens.

“We’re riding the crest of a wave,” says Commercial Director Mark Wheeler. “From the projects completed so far this year, both in the UK and beyond, to those we’re currently working on, it’s been truly inspiring to see all our fantastic teams pull together and achieve excellence across the board.”

Among those completed projects in the past six months are a 300sqm ISO6 Medical Device facility in Staffordshire, 140sqm ISO8 Optical cleanroom in Kent, 12sqm ISO7 Injection Moulding bespoke Isopod Rapid Cleanroom in Gloucestershire, 200sqm ISO7 Micro-electronics modular in Cambridge, 12sqm ISO7 Critical Systems Engineering Isopod in Manchester and two innovative 3sqm ISO7 ‘mobile airlock’ Softwall Isopods for Medical Moulding in Burton-on-Trent.

“We’re delighted with the high standards we’ve continued to set so far this year, but there are plenty of big jobs to tackle and we’re all relishing the challenge.”

The Guardtech Group projects currently under way include a 400sqm ISO8 Research & Product Development facility in Cambridge, 100sqm ISO7 & 8 Research & Development in Surrey, 1800sqm ISO8 Aerospace facility in the South of England, 125sqm ISO5 & 8 Research & Development controlled environment in Devon, 100sqm ISO5 & 7 Research & Development laboratory in Staffordshire, 300sqm ISO5, 6 & 7 modular cleanroom for technology innovators in Germany and a 130sqm ISO8 modular cleanroom for Electronics manufacturing specialists in Zurich.

All this activity in the same period that Guardtech’s Commercial Team have attended exhibitions across a variety of sectors – with shows including Medical Technology UK, Making Pharmaceuticals, the Cleanroom Technology Conference and Med-Tech Expo, as well as the likes of Medical Technology Ireland, SEHTA Expo, Lab Innovations and more still to come this year.

“It’s been super-busy for sure,” adds Mr Wheeler, “but we wouldn’t have it any other way. We’re also moving into our new premises imminently – a brilliant, fresh and dynamic new office space that reflects where we’re at as a business right now.”

For more information on the Guardtech Group, visit www.guardtechgroup.com, call 0330 113 0303 or email sales@guardtech.com.

Head to www.guardtechcleanrooms.com to check out the Group’s new specialist modular construction website.

Turnkey construction arm Cleanroom Solutions and modular specialists Guardtech Cleanrooms are currently working on seven significant projects between them, including large builds in Germany and Switzerland.

The Group completed a 60sqm ISO6 & 7 Electronics Testing modular in Ireland in May and shipped a 20sqm ISO8 Automotive Isopod Rapid Cleanroom to a client in Morocco last month, having already provided a customer with 30sqm & 45sqm ISO7 Electronics Isopods in Denmark in the spring.

This is all alongside a 60sqm ISO7 Research & Development CleanCube Maxi that was constructed at Guardtech’s UK manufacturing facility and then delivered to Sweden, ready for immediate deployment.

The Group unveiled brand-new websites for portable solution CleanCube (www.cleancube.co.uk) and Cleanroom Solutions (www.cleanroom-solutions.co.uk) earlier this year and are delighted to reveal a new subsite for Guardtech Cleanrooms has just been launched at www.guardtechcleanrooms.com.

It all adds up to another highly fruitful – and busy – six months for the Haverhill-based cleanroom kings and queens.

“We’re riding the crest of a wave,” says Commercial Director Mark Wheeler. “From the projects completed so far this year, both in the UK and beyond, to those we’re currently working on, it’s been truly inspiring to see all our fantastic teams pull together and achieve excellence across the board.”

Among those completed projects in the past six months are a 300sqm ISO6 Medical Device facility in Staffordshire, 140sqm ISO8 Optical cleanroom in Kent, 12sqm ISO7 Injection Moulding bespoke Isopod Rapid Cleanroom in Gloucestershire, 200sqm ISO7 Micro-electronics modular in Cambridge, 12sqm ISO7 Critical Systems Engineering Isopod in Manchester and two innovative 3sqm ISO7 ‘mobile airlock’ Softwall Isopods for Medical Moulding in Burton-on-Trent.

“We’re delighted with the high standards we’ve continued to set so far this year, but there are plenty of big jobs to tackle and we’re all relishing the challenge.”

The Guardtech Group projects currently under way include a 400sqm ISO8 Research & Product Development facility in Cambridge, 100sqm ISO7 & 8 Research & Development in Surrey, 1800sqm ISO8 Aerospace facility in the South of England, 125sqm ISO5 & 8 Research & Development controlled environment in Devon, 100sqm ISO5 & 7 Research & Development laboratory in Staffordshire, 300sqm ISO5, 6 & 7 modular cleanroom for technology innovators in Germany and a 130sqm ISO8 modular cleanroom for Electronics manufacturing specialists in Zurich.

All this activity in the same period that Guardtech’s Commercial Team have attended exhibitions across a variety of sectors – with shows including Medical Technology UK, Making Pharmaceuticals, the Cleanroom Technology Conference and Med-Tech Expo, as well as the likes of Medical Technology Ireland, SEHTA Expo, Lab Innovations and more still to come this year.

“It’s been super-busy for sure,” adds Mr Wheeler, “but we wouldn’t have it any other way. We’re also moving into our new premises imminently – a brilliant, fresh and dynamic new office space that reflects where we’re at as a business right now.”

For more information on the Guardtech Group, visit www.guardtechgroup.com, call 0330 113 0303 or email sales@guardtech.com.

Head to www.guardtechcleanrooms.com to check out the Group’s new specialist modular construction website.

Products & Services

Isopod Hybrid Cleanroom

Isopod Softwall Cleanroom

Isopod Hardwall Cleanroom

Team

| Name | Role | Telephone | |

| Mark Wheeler | Commercial Director | m.wheeler@guardtech.com | 03301130303 |

| Andrew Cressey | Commercial Manager | a.cressey@guardtech.com | 03301130303 |

| Steve Bawa | Business Development Manager | s.bawa@guardtech.com | 03301130303 |